#ITMA Asia + CITME Singapore 2025

Savio innovations at ITMA Asia Singapore 2025

The spotlight will be on three flagship machines:

+ Proxima Smartconer® – the next-generation winding platform

+ Lybra Smartspinner® – the versatile air-jet spinning solution

+ Phoenix – the new assembly winder for precision yarn preparation

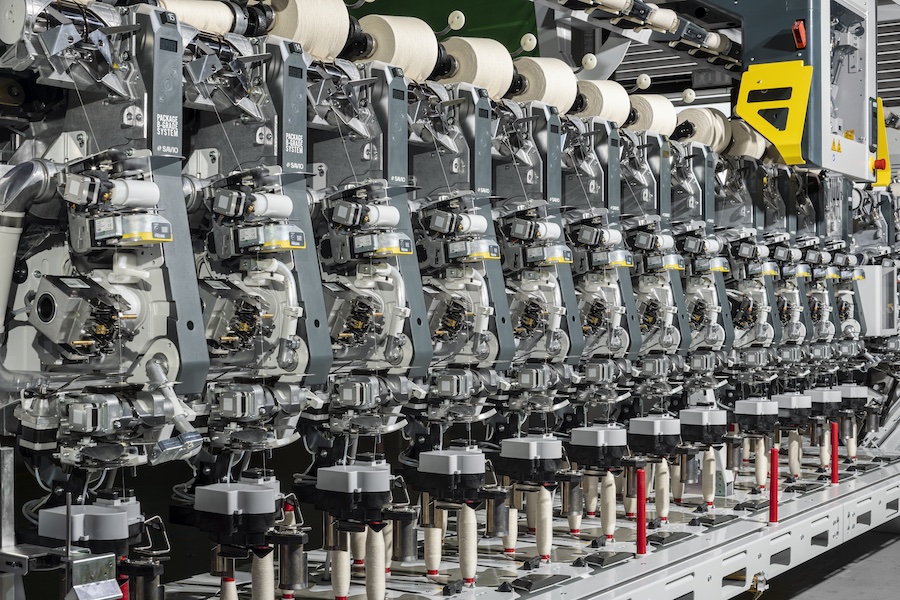

Proxima Smartconer® – "Smart Winding Intelligence"

Savio’s Proxima Smartconer® is now available in a full range of configurations: fully automatic, manual feeding, cone-to-cone, Duo Lot, and large bobbin feeding for carded wool sector. The winding platform integrates energy-saving features, optimized bobbin flow, and AI-powered functions, along with Savio Insight, a web-based system for real-time production monitoring and control.

Key upgrades include:

+ Savio Insight: Enables remote setup, data tracking, and performance analysis to support informed decision-making in the winding process.

+ Newly designed and patented suction nozzle on preparation area: Improves yarn-end capture efficiency and reduces energy consumption. A smart solution, designed to increase performance and reduce operating costs, while maintaining high standards of reliability and quality.

+ AI-driven features: Adaptive tension control, smart metering, and intelligent bobbin flow management enhance automation and precision.

Proxima is designed to deliver high productivity, low energy consumption, premium yarn quality, and seamless data connectivity—a strategic asset for textile manufacturers.

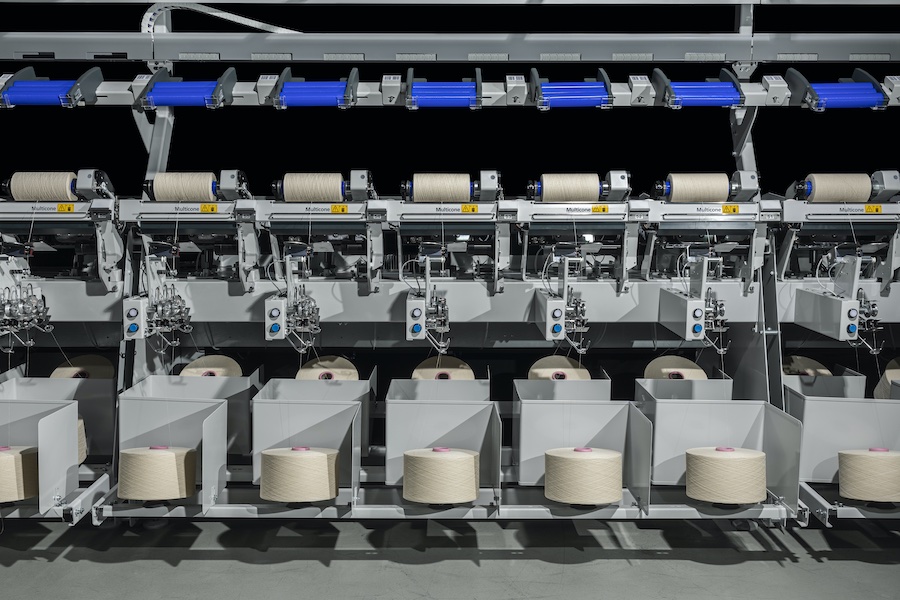

Phoenix Assembly Winder – "Precision Meets Performance"

After having debuted in Singapore 20 years ago, Savio’s Phoenix assembly winder comes back with improved digital features. Phoenix is Savio’s latest addition for precision winding assembly, combining high productivity with exceptional package quality and low operating costs. Yarn packages processed on assembly winders then go to feed Two-for-One Twisters: Phoenix is thus a natural extension to Savio’s product range to fully integrate the twisting and winding process .

Phoneix benefits:

+ Yarn take-up speed: up to 1000 m/min.

+ Suitable for all discontinuous fiber yarns (cotton, wool, silk, linen, blends) from Ne 1 to Ne 140.

+ Savio Multicone digital thread guide reduces setup time and optimize package formation for superior downstream twisting results.

Lybra Smartspinner® – "We Spin Different"

We spin different with a versatile and smart machine: Savio’s air-jet spinning machine Lybra Smartspinner® has been developed with an original spinning technology to serve customers in specific applications of textile production: knitting, home textiles, sunshades. A standout feature of Lybra is the Multi Blend System, which allows to feed onboard two slivers directly into the spinning chamber. Fibers are blended in real time, enabling:

+ On-the-fly blend composition changes via machine PC.

+ Cost savings and streamlined preparation lines.

+ Creation of unique material and color blends, including melange effects.

Lybra offers versatility, efficiency, and ease of use, empowering manufacturers to achieve high production rates with reduced processing costs.