#Dyeing, Drying, Finishing

Tonello launches “THE LAUNDRY (R)EVOLUTION“ web series

“Talking to all players of our business, we realized the increasingly more important request of the real data concerning the garments finishing process“ said Alice Tonello, marketing and R&D Director at Tonello “so we decided to create this innovative and unique web series were we explain in an easy and immediate way, how we manage to create innovation that allows our machineries to use 7 liters of water to wash a pair of jeans instead the usual 150 liters used in regular production”.

Episode #1 : THE BEGINNING

is already live on the web and explain why we decided to take up the challenge of reducing waste in the amount of energy and environmental resources used

https://youtu.be/uerpNu-TfFQ

Episode #2 : THE CONCRETENESS

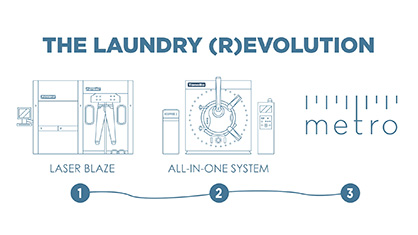

The revolution comes alive: improving performance while at the same time, reducing consumption. The overview introduces the three simple and decisive steps for achieving this goal. For garment finishing, it marks the beginning of a new era.

https://youtu.be/MYbpxZrH0V4

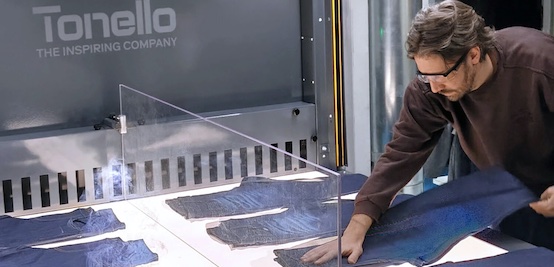

Episode #3 – First step: LASER BLAZE

Saying goodbye to manual scraping, thinking big means taking denim design to the next level. Thanks to Tonello’s research, creativity enters the finishing process with the strength and awareness of a protagonist.

Episode #4 - Second step: THE ALL-IN-ONE-SYSTEM AND OBLEACH...TOGETHER!

NoStone®, ECOfree 2, UP, Core, and OBleach (the new Tonello ozone process that "bleaches" jeans without using permanganate), generate an almost infinite number of creative solutions. In addition, all wet processes are carried out in a single machine, thus drastically reducing consumption and the waste of resources.

Episode #5 - Third step: Metro, the measure of transparency

With Metro, the facts are incontrovertible and only the reality, proven by data, count. There is no possibility for manipulation, only constant, reliable, and automatic performance measurement of the entire process. Detailed, analytical, or synthetic data according to necessity, but always objective and accurate in order to keep improving on the path to sustainability, savings and respect for the environment.

“We created this 5 episodes which will give to all the players of our business, real data in the name of practicality, transparency, responsibility.” continues to tell us Alice Tonello “5 videos that introduce you to the protagonists, the stars of an authentic revolution that represents a radical paradigm change as well as our contribution to helping the planet.”