#Dyeing, Drying, Finishing

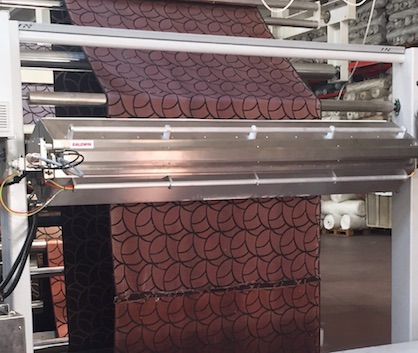

Baldwin announces two successful TexCoat G4 installations in Turkey

New technology increases productivity for upholstery manufacturers Adoksan and Boyteks

For Adoksan and Boyteks, the TexCoat G4 eliminates a step in the finishing process, enabling considerably increased production efficiency. Because this precision application technology applies the exact amount of chemistry required, the wet pick-up level and water consumption can be reduced by up to 50 percent, resulting in up to 50 percent less energy for drying. This translates to a more sustainable, cost-efficient process, and a faster line speed for these upholstery producers. Moreover, in fabric or chemistry changeovers, 100 percent of the chemistry is recycled with zero waste.

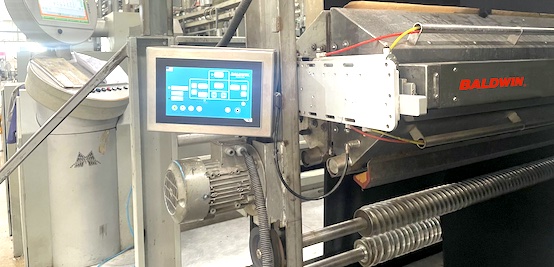

“Our new finishing system offers quality results and other advantages, supporting our partners in achieving great ROI along with sustainable production,” said Eric Norling, Vice President, Precision Application Technology for Baldwin. “These two TexCoat G4 orders are of significant importance for Baldwin, and we are excited about both installations.”

The TexCoat G4 was introduced during ITMA in June 2019. Spot Ltd., under the leadership of Cengiz Kahraman, has been representing Baldwin’s precision application technology product line for the textile market in Turkey since 2016.