#Dyeing, Drying, Finishing

BW Converting to promote sustainable finishing solutions with A.T.E. at Techtextil India 2025

Highlighting chemistry, water, and energy savings with TexCoat® G4 precision spray finishing technology

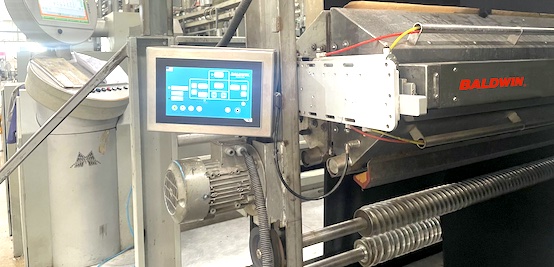

BW Converting’s proven TexCoat® G4 precision spray finishing technology will be featured in the A.T.E. booth, where visitors can learn how the system enables mills and finishers to reduce chemical waste, minimize water usage, and significantly cut energy consumption - all while enhancing product quality and process control.

“India represents one of the most dynamic and promising textile markets in the world,” said Yiannis Vasilonikolos, Global Sales Leader, Textiles, BW Converting. “Through our collaboration with A.T.E., a respected and established leader in India’s textile engineering sector, we’re excited to discuss how TexCoat G4 can help local manufacturers achieve both sustainability and profitability in finishing operations.”

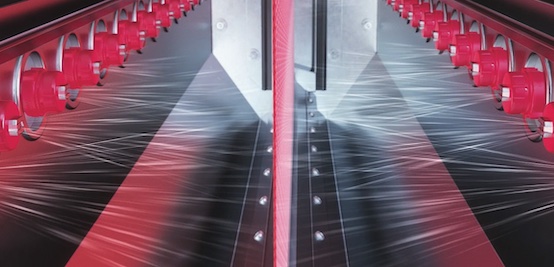

The TexCoat G4 system uses Precision Application Technology (PAT) to apply chemistry with pinpoint accuracy, on one or both sides of the fabric, with zero contamination, overspray, or dilution. By eliminating pad baths and reducing wet pick-up by up to 50%, TexCoat G4 helps textile producers achieve faster throughput, consistent results, and substantial resource savings.

“Technical textiles and home furnishings are growing segments in India, and mills are increasingly focused on operational efficiency and sustainability,” added Rick Stanford, Vice President of Global Business Development, Textiles, BW Converting. “Our precision spray technology delivers on both fronts, helping manufacturers optimize output, lower costs, and reduce their environmental impact.”

Building on the proven precision and uniformity of its TexCoat® technology, BW Converting recently introduced its new TexChroma digital spray dyeing system at ITMA Asia in Singapore, further expanding the company’s capabilities in sustainable textile processing. BW Converting’s local team and representatives from A.T.E. will be on hand throughout the Techtextil India show to discuss how TexCoat® G4 and other advanced finishing solutions can support the country’s expanding technical textile sector.

To learn more about BW Converting’s textile innovations, visit bwconverting.com.