#Dyeing, Drying, Finishing

BW Converting’s Baldwin brand validated by Fashion for Good and Apparel Impact Institute

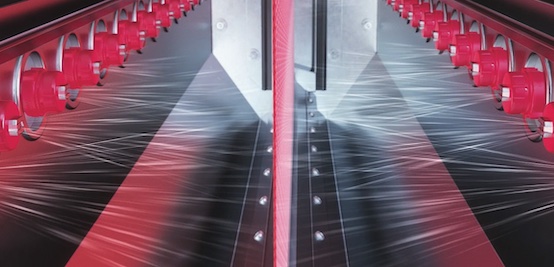

TexCoat G4 replaces traditional pad-based applications with non-contact precision spray technology, applying chemistry only where it is needed. The system delivers 40–50% energy savings, reduces water consumption and chemical use by up to 50% and eliminates chemical waste during job changeovers. These benefits help mills achieve significant sustainability targets while improving profitability and throughput.

“Being recognized by both Fashion for Good and Aii underscores the impact of TexCoat G4 not only as an innovative finishing technology but as a verified climate solution,” said Yiannis Vasilonikolos, Global Sales Leader, Textiles, BW Converting. “We are proud that the data confirms what our customers experience every day: measurable reductions in energy, water and carbon footprint, paired with consistently high finishing quality. Together, this validation strengthens our ability to help textile producers meet the dual goals of sustainability and competitiveness.”

Reflecting on the real-world impact of the technology, Andrea Mariani, Production Director at Oreste Mariani, a leading European textile finisher, shared:

“At Oreste Mariani we have been running BW Converting’s Baldwin TexCoat G4 since 2022. The system has helped us significantly reduce energy and chemical consumption while maintaining high finishing quality. Independent trials, such as the BluWin BAT+ study at our mill, confirmed these savings in real production conditions. In 2024, we also installed BW Converting’s Baldwin Corona Pure for textiles, which allowed us to achieve the maximum level of water repellency while eliminating an additional wash step from our process. For us, this means both improved product performance and lower resource use. Equally important, we have experienced excellent support from the BW Converting team and a very high level of reliability from their equipment. Together, TexCoat G4 and Corona have become important technologies in our sustainability journey, helping us reduce environmental impact, cut costs and continue to deliver high-quality fabrics to our customers.”

The validation follows successful field trials in Europe and Asia, where TexCoat G4 has demonstrated substantial resource savings with no compromise to fabric quality. As part of Aii’s registry, the technology will now be visible to leading apparel brands and retailers that are actively sourcing scalable solutions to decarbonize textile wet processing. The full case study is available here: Aii Case Study – Precision Spray Finishing Technology.

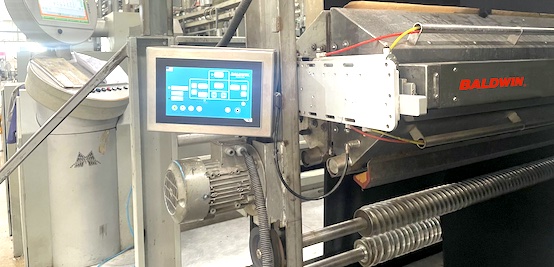

TexCoat G4’s patented non-contact spray process also streamlines operations by reducing downtime, enabling rapid changeovers and supporting traceability through full Industry 4.0 integration.

To learn more about TexCoat G4 and BW Converting’s full portfolio of textile finishing technologies, visit bwconverting.com.