#Digital Printing

Epson debuts first industrial direct-to-garment printer bringing new levels of customization to growing digital textile market

Epson today announced its first industrial direct-to-garment printer – the SureColor® F3070. Designed to provide low total cost of ownership (TCO) and reliability for exceptional performance and savings in high-production print shop environments, the SureColor F3070 is Epson’s first direct-to-garment printer to leverage dual printhead technology and a bulk ink pack system, providing remarkably low ink cost and minimized waste compared to Epson cartridge systems. It touts all new automatic garment height adjustment and easy user maintenance features to increase production and reduce downtime for garment print shops creating custom apparel. The new printer will be on display in Epson’s booth (#2049) at Impressions Expo in Long Beach, Calif. from Jan. 17-19, 2020.

“The printed textile market is seeing tremendous growth, complemented by new printing technology innovation,” said Tim Check, senior product manager, Professional Imaging, Epson America, Inc. “We are committed to driving the digital textile market and excited to expand Epson’s award-winning product line to deliver our first industrial direct-to-garment printer for high-production print shops. Designed for mid-to-large size garment printers looking for a high-production, cost-effective equipment, the SureColor F3070 can produce a full-size shirt in about a minute, allowing shops to print hundreds of shirts per day.”

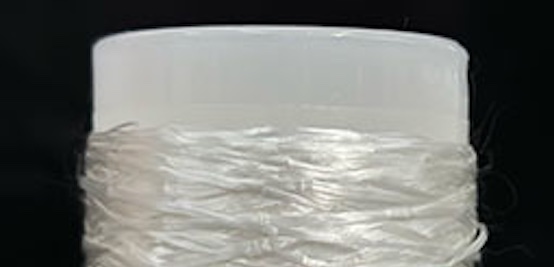

Ideal for digitally printing custom garments on variety of fabric types including cotton, linen and rayon, the SureColor F3070 is designed to meet the increasing market demand for unique clothing driven by the millennial population in the U.S.1 The printer leverages a new dual 2.6-inch PrecisionCore® printhead for high-quality output at production speeds with true one-pass printing for both color and White ink. Coupled with the first bulk ink system integrated into an Epson direct-to-garment printer, it is capable of housing 1.5 liters per color and 3.0 liters of White ink for less frequent refilling, lower operating costs, and less waste.

First ever automatic printhead height adjustment is set based on garment thickness and texture for optimal print quality without user interference, and easily switches between thin t-shirts and thick sweatshirts with less downtime between garments. Built for reliability, the SureColor F3070 features an ultra-durable linear rail system and CNC milled print carriage, designed for years of production, and features user serviceable parts, including printheads, and low maintenance time ideal for high production print on-demand service providers, fulfilment houses and in-house print on-demand production.

More about the SureColor F3070

Delivering high image quality, productivity and reliability in an affordable, highly intuitive design, the SureColor F3070 offers advanced features for the garment printing industry, including:

- PrecisionCore Printhead Technology – Dual 10-channel printheads with 16,000 nozzles delivering industrial quality output at impressive production speeds

- Bulk Ink System – Replaceable bulk ink packs for less frequent ink refilling and lower costs compared to our ink cartridge systems

- High-Quality Direct-to-Garment Printing – Epson UltraChrome® DG inks* are durable, vibrant and safe, with outstanding color performance, plus equal pricing for color and White inks

- Automatic Printhead Adjustment – Optimized for garment thickness for improved print quality without user intervention

- Low Total Cost of Ownership – Low maintenance time and cost with dedicated cleaning solution channels and fabric head wiper system

- Fast Loading for More Productivity – Easy-to-use, all-new quick-load platen reduces traditional hoop platen load times

- Intuitive, Easy-to-Learn Workflow – Updated Epson Garment Creator Software, available for macOS® and

- Windows®, includes cost estimator, text tools, hot folders, and automation SDK

- Designed Exclusively for Direct-to-Garment Printing – An entirely purpose-built system featuring Epson’s PrecisionCore printhead, Epson UltraChrome DG ink system and robust hardware

- Scale Seamlessly – Scale production capability with additional printers featuring an easily repositionable compact design that operates on standard 120v power

Support & Availability

The SureColor F3070 (estimated MSRP $49,995) offers a standard Epson PreferredSM Limited Warranty, limited on-site warranty with U.S.-based phone support. The Epson SureColor F3070 will be available in July 2020 through Epson Authorized Professional Imaging Resellers. For more information, visit www.proimaging.epson.com.