#Denim

Tonello at Kingpins: from deep white to pure indigo, a show within a show.

Yes, we will be there again this year. With a definitely "inspiring" booth, a real show within the show, divided into 3 acts:

1. DyeMate, the ozone, THE Laser

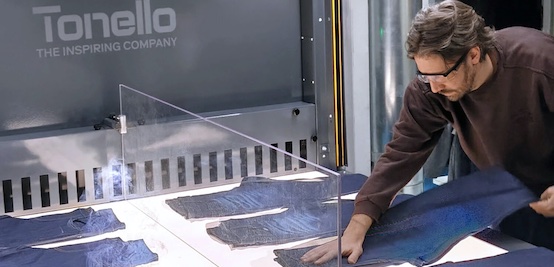

DyeMate is Tonello's new "patent-pending" technology that revolutionizes and reinterprets the traditional indigo garment dyeing process, taking it to a new evolutionary stage and making it automatic and repeatable, efficient and sustainable: carried out in a nitrogen atmosphere, without oxygen, with controlled reduction and oxidation, to achieve results that are perfectly comparable, in terms of charm, perceived authenticity and "aesthetic flavor," to those of denim that fades and becomes vintage with the passage of time. With DyeMate, technology is at the service of beauty.

We will present at Kingpins a collection of garments that take the use of ozone technologies beyond known limits, with super bleach effects that were impossible to achieve until yesterday, but are now, thanks to the OBleach, EGO and O-Zone triad, finally a reality. In fact, we have totally redefined the garment bleaching process, to say goodbye forever to harmful chemicals such as chlorine and permanganate, in favor of sustainable and healthy production.

The entire collection will be embellished and finished with unique and distinctive aesthetic solutions and details: the totally natural overdyeing of Wake, the ultra-thin graphics made with THE Laser Lab, the perfect and infinitely reproducible breakages of THE Laser T and TM.

Once again, in short, we have taken the laser beyond itself.

1. Collections, design, collaborations

The MSP - Most Sustainable Product - collection, developed together with Kingpins and Denim House, designed by Piero Turk and Serena Conti, and processed in Tonello's Research and Development Center with the latest responsible finishing technologies, returns again this year.

Then at Kingpins we will present another project we care a great deal about: it is ONE Denim, a collection that aims to combat resource waste in the denim industry by demonstrating concretely how many new denim garments could be made from a single fabric by optimizing processes and choosing appropriate technologies and production methods. The fabrics chosen are from Sharabati Denim, the design is by Piero Turk, and the collection is processed by Tonello.

1. SA-KE, the purpose for doing something

This project was born out of a dialogue between Tonello's technology and the creativity of British designers Sadia Rafique and Kelly Harrington, who produced as many as 70 artworks that are partly physically present at Kingpins and partly published in a book-zine that tells the philosophy and logic of this unique and original work. A work that precisely combines technology, expressive research and all new forms of image generation, across the boundary between natural and artificial, but still totally human. And using denim fabrics as canvases on which to draw fantastic and material worlds.

With SA-KE, Tonello's technology once again meets and supports creativity.