#Composites

Highlighting excellence at the JEC Composites Innovation Awards ceremony

An exciting time for the composites industry

The JEC Composites Innovation Awards were launched in 1996 and have highlighted the achievements of 1,900 companies in the past 24 years. One hundred ninety-eight companies and 475 partners have been recognized for their innovation in the field of composites. The JEC Composites Innovation Awardsfocus on the following criteria when selecting winners in the composites industry: involvement in the value chain, technical sophistication, and commercial potential.

After pre-selecting 33 finalists, the jury selected one winner per category (Additive Manufacturing, Aeronautics, Automotive, Construction Infrastructures & Civil Engineering, Design & Furniture, Maritime Transportation & Shipbuilding, Process, Railway Vehicles & Infrastructure, Recycling, Space, Sports & Healthcare). These represent some of the most advanced innovations developed by talented professionals, which were recognized during this ceremony.

“The JEC Composites Innovation Awards do more than simply confer awards. They are intended to be a source of inspiration for the industry and a driver of excellence for all winners. This is a highly anticipated, not-to-be-missed event every year for the composites industry,” explained Franck Glowacz, Innovation Content Leader at JEC Group.

And the winners are...

Thirteen companies, from large well-known groups to small, talented teams, were recognized for their innovations!

- In the “Additive Manufacturing” category, the Spanish company Eurecat was recognized for its innovative CFIP Technology, a new post-processing technology that uses continuous fibers to strengthen a variety of parts, no matter the material or manufacturing technology.

- For the “Aeronautics” category, the French team of theInstitut de Soudure Groupe & Arkemareceived an award for their “Innovative Solutions for Welding of TP Composites,” a newly developed and patented solution used for very high performance welding for thermoplastic composites.

- For the “Automotive” industry, the German manufacturer Volkswagenwas recognized for its “Lightweight FRP Center Tunnel (LehoMit-Hybrid),” an innovative and profitable thermoplastic structural hybrid car body component that is suitable for high-volume production, which can be introduced prior to cathodic dip coating with the corresponding assembly technology.

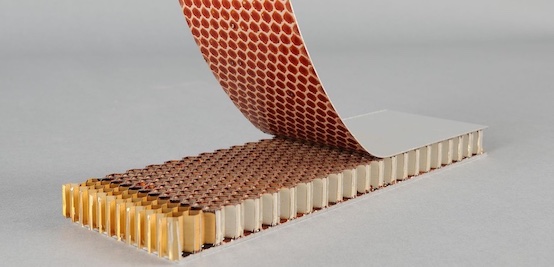

- In the “Construction, Infrastructures & Civil Engineering” category, the Swiss team at Carbo-Link received accolades for their CL RESTRAP technology consisting of thin cured CFRP prepreg tapes continuously wound in a loop to form a flexible carbon strap. These have an unlimited lifespan and are used to reinforce concrete girders of all sizes, in any infrastructure.

- For the “ Design & Furniture” sector, the Finnish company Mecelec Composites was recognized for its “Mass-produced Flax Fiber Roofs,” the first application of flax fiber BMC for mass production.

- The Finnish company Norsepower Oy Ltd. also received an award, this time in the “Maritime Transportation & Shipbuilding” category. Their Norsepower Rotor Sail Lightweight Solution helps freight and passenger vessels to reduce fuel costs by 5 to 30 % by improving vessels’ propulsion systems through the use of wind for additional propulsive power.

- In the “Process” category, the Austrian company Engel Austria was awarded for its “Line for Tailored Thermoplastic Composite Blanks,” an innovative line consisting of a pick-and-place stacking cell and a heating and cooling consolidation unit capable of producing a customized thermoplastic blank within a cycle time of one to three minutes.

- For the “Railway Vehicles & Infrastructures” sector, the spotlight was shone on the British company Far-UK Ltd for its “Project BRAINSTORM,” a new design of incredibly lightweight rail vehicle frames that are woven from carbon fiber composites into a series of tubes for lower investment and manufacturing costs as well as carbon emissions.

- For the field of “Recycling,” the Thai company Cobra International was awarded for its “Closed Loop Recycling of Epoxy Composites,” a sustainable solution for closed loop recycling of infused epoxy mold tools and thermoset epoxy RTM watersports fins for starboard and MFC.

- In the “Space” category, the Korean company Hankuk Carbonreceived accolades for its “Lightweight & Liner-less Carbon Subscale Cryotank” that can reduce the weight of a space launcher by 30% by replacing the current fuel tank with an uncoated carbon composite cryotank.

- In the “Sports & Healthcare” industry, Asics Corporation from Japan was recognized for its “Future of Sprints: Spike-Less CFRTP Sprinting Shoe,” a breakthrough shaping methodology using pre-formed, randomly-oriented ultra-thin CFRTP tapes.

- The “JEC Composites Magazine” Special Award was bestowed on Cookson Precious Metalsfor its “3D-Printed Bushings for Glass Fiber Production.”

- Finally, the general public voted to award the French company Stratiforme Industriesfor its “DESTINY Thermoplastic Resin Train Front End,” which aims to launch a new range of components for commercial aircraft interior fittings and rail applications based on thermoplastic composites.

The very best of the entire international composites community was truly on display at this ceremony, demonstrating that these awards have continued to remain on the cutting edge of innovation and creative capacity even in these unusual times.