Composites

JEC Innovation Awards 2018: 30 finalists exemplify the best of composite innovation worldwide

JEC Group, the largest composites organization in the world, presents a new format for its prestigious JEC INNOVATION AWARDS competition, announcing today the 30 finalists divided into 10 categories. A renowned jury of experts will select one winner per category. The 10 winners will be announced in a ceremony to be held on JEC World 2018 on March 7, 2018.

"Like every year, we received hundreds of applications for the JEC Innovation Awards, this success truly shows that this program is a recognized tool to spot and promote Innovations in the Composites Industry", says Ms. Frédérique Mutel, JEC Group President and CEO. "I am particularly delighted to introduce another brand new feature to this program: the Public vote. Indeed, our jury will choose the winners according to specific criteria such as involvement of partners in the value chain, technicity or again market application, but the general audience will be able to vote for their favorite Innovation, online or through JEC World Mobile Application!

The public vote winner will be announced at the end of JEC World and people can vote before and after the ceremony!" she adds.

A jury of experts

10 experts from around the world will reward 10 Composites Champions who presented their Innovations in the End-using markets for Composites. The panel of judges consists of:

- Anurag BANSAL, Manager Global Business development at ACCIONA INFRAESTRURAS (Spain)

- Christophe BINETRUY, Professor at ECOLE CENTRALE DE NANTES (France)

- Robert BUCHINGER, Chief Technology Officer at DAS ENERGY (Austria)

- Grahame BURROW, Global President of MAGNA (USA)

- Ali CALISKAN, CEO of KORDSA (Turquie)

- Dominique DUBOIS, CEO of CARBOMAN Group (France)

- Chantal FUALDES, Airbus Composite Airframe Executive Expert at AIRBUS (France)

- Karl-Heinz FULLER, Manager hybrid materials, concepts and AMG at DAIMLER (Germany)

- Sung HA, Professor at HANYANG UNIVERSITY (Korea)

- Kiyoshi UZAWA, Professor/Director (Ph.D) at INNOVATIVE COMPOSITE CENTER (Japan)

A new trophy representing the industry

For the occasion, a brand new trophy has been created. The new Composites trophy will combine parts from many different composite materials such as glass fiber, carbon fiber or again natural fiber, representing the diversity of the Industry.

JEC INNOVATION AWARDS CEREMONY JEC WORLD – Paris Nord Villepinte March 7, 2018

AEROSPACE • APPLICATION

INFUSION TECHNOLOGY FOR AN AIRCRAFT WING

Nominated for a JEC Innovation Award: AeroComposit, JSC (Russia) and partner Solvay (UK)

Using infusion technology to manufacture primary structural elements for an aircraft wing, making it possible to build integral composite structures with high elongation and a complex aerodynamic form.

Key Benefits:

- Lighter aircraft structures

- Lower cost of equipment

- Reduced total time and power spendings

- More flexibility in production

- Lower porosity, better quality of parts

MODULAR THERMOPLASTIC STIFFENING PANELS

Nominated for a JEC Innovation Award: Fraunhofer ICT (Germany) and partners Airbus Operations GmbH (Germany), Laser Zentrum Hannover e.V. (Germany), TenCate Advanced Composites BV (The Netherlands), ElringKlinger AG (Germany), KMS Automation GmbH (Germany)

Modular thermoplastic stiffening panels for aerospace applications. The panels lead to weight and cost savings, in addition to easy adaptation. They are recyclable and exhibit outstanding flame resistance.

Key Benefits:

- Weight savings for new generations of aircraft

- Modular design allows easy adaptation to use case

- Easy integration by laser transmission welding Integrated functionality via hybrid moulding

- Economical manufacturing for high volumes

POLYURETHANE-RTM NOSE CONE FOR JET ENGINES

Nominated for a JEC Innovation Award: University of Applied Sciences Rapperswil (Switzerland) and partners FACC (Austria), Rühl Puromer GmbH (Germany), Isotherm AG (Switzerland), WPT, TU Dortmund (Germany)

Using the high-pressure polyurethane-RTM process, jet engine nose cones with optimized properties can be manufactured in a fraction of the time commonly needed today.

Key Benefits:

- Better impact and abrasion properties

- Dramatically reduced production time and costs

- Optimized and easier processing

- Prolonged operating time

- Lower material costs

AEROSPACE • PROCESS

COMPLEX STRUCTURAL APPLICATIONS OF MAI SANDWICH TECHNOLOGY

Nominated for a JEC Innovation Award: Airbus (Germany) and partners BMW Group (Germany), Technical University of Munich (TUM) (Germany), Neue Materialien Bayreuth GmbH (Germany), Werkzeugbau Siegfried Hofmann GmbH (Germany), BASF SE (Germany), Foldcore GmbH (Germany), Neenah Filtration (Germany), SGL Carbon GmbH (Germany)

Production of a cost-effective, complex 2.5D thermoplastic composite sandwich structure with a very short cycle time of less than 5 minutes for aerospace materials and 2.5 minutes for automotive materials.

Key Benefits:

- Net-shaped 2.5D complex structural sandwich part

- High functionality through injection directly on skin

- Prevention of voids in the outer layer due to the process

- Very economic due to short cycle times in one device

- Cross-industry mid- and large-scale production

MOULD-LESS MONOCOQUE MANUFACTURING PROCESS

Nominated for a JEC Innovation Award: M. Torres Diseños Industriales SAU (Spain)

New manufacturing process for large monocoque composite structures with fully-integrated reinforcements and without the need for complete moulds.

Key Benefits:

- Dramatic tooling reduction, up to 70%

- Global manufacturing costs reduction, up to 40%

- Weight reduction due to the elimination of fasteners

- Topological optimization of the reinforcements

- Process flexibility breakthrough

FULL-OoA TP WELDED PRIMARY AIRFRAME

Nominated for a JEC Innovation Award: Stelia Aerospace (France) and partners Porcher Industries (France), Sintex NP (France), Compose Tool (France), CETIM (France), Aviacomp SA (France), Institut de Soudure / Composite Integrity (France)

Full-OoA thermoplastic airframe with industrial dynamic induction welding demonstration using carbon tape for future fuselage applications and multi-functional parts produced by an overmoulding process.

Key Benefits:

- Induction welding demonstration for fuselage panels

- 100% OoA thermoplastic structure

- New design opportunity with an overmoulding process

- Fully-automated, cost-effective process

- 100% recyclable airframe (TP)

AUTOMOTIVE • APPLICATION

COMPOSITE LIGHTWEIGHT AUTOMOTIVE SUSPENSION SYSTEM

Nominated for a JEC Innovation Award: Action Composites (China) and partner Dr. Ing. H.c. F. Porsche AG (Germany)

For the first time in a series production car, the stabilisers on the front and rear axles are made of carbon, as are their coupling rods, for outstanding performance.

Key Benefits:

- 55% weight saving

- Short cycle time: less than 6 minutes

- Reduced CO2 emissions

- CFRP capability for suspension parts

- Opening a new market for CFRP

LIGHTWEIGHT SEAT BACK FRAME FOR SUV SECOND ROW

Nominated for a JEC Innovation Award: Hanwha Advanced Materials (South Korea)

Development of the world’s first SUV second-row seat back frame using composite materials.

Key Benefits:

- Low weight

- Short cycle time and reduced number of parts

- Recyclable

DEVELOPMENT AND MANUFACTURING OF A FULL-CFRP CAR BODY

Nominated for a JEC Innovation Award: Kangde Composites Co., Ltd (China) and partners KDX Roding Europe Automobile (Germany), Faststar New Energy Automobile (China)

Lightweight CFRP hypercar body.

Key Benefits:

- Using the mechanical advantages of carbon fibre

- Reduced part number and processing difficulty

- Improved endurance, lower emissions and high noise & vibration characteristics

- Technical reserve for future mass production

AUTOMOTIVE • PROCESS

MASS PRODUCTION OF CFRP STABILIZERS AND DROP LINKS

Nominated for a JEC Innovation Award: Action Composites (China) and partner Dr. Ing. H.c. F. Porsche AG (Germany)

For the first time in a series production car, the stabilisers on the front and rear axles are made of carbon, as are their coupling rods, for outstanding performance.

Key Benefits:

- 55% weight saving

- Short cycle time: less than 6 minutes

- Reduced CO2 emissions

- CFRP capability for suspension parts

- Opening a new market for CFRP

HIGH-VOLUME CFRP PRODUCTION: CARBON REAR WALL MODULE

Nominated for a JEC Innovation Award: Audi AG (Germany) and partners Voith Composites GmbH & Co. KG (Germany), Dow Automotive (Switzerland), Zoltek Corp. (USA)

For the first time, the full potential of CFRP can be used in high-volume production thanks to a newly developed rear wall module and cost- efficient production technologies.

Key Benefits:

- Cost-efficient, high-performance composite solution

- Functional system integration in a body part module

- New manufacturing technology for high-volumes

- Pre-assembly parallel to the assembly line

- Maximum design freedom of CFRP in high-volume production

COMBINING CFRP AND INJECTION MOULDING FOR SERIES PRODUCTION

Nominated for a JEC Innovation Award: Dr. Ing. H.c.F. Porsche AG (Germany) and partner Plan B GmbH (Germany)

Innovative manufacturing method for a vehicle substructure combining CFRP and injection moulding to create a flexible clip as an overmoulded fastener onto a rigid component.

Key Benefits:

- Using the advantages of thermosets and thermoplastics

- Quick and robust manufacturing of the components

- Easy substitution of pure thermoplastic parts

- Less expansive than complex-geometry CFRP parts

CONSTRUCTION & INFRASTRUCTURE

BELOW THE LINE: CONCRETE PIPE REPAIR WITH CARBON FIBRE

Nominated for a JEC Innovation Award: Grupo Navec (Spain) and partners Saertex GmbH (Germany), Henkel (Germany)

In-situ manufacturing of a carbon fibre pipeline by means of an epoxy resin infusion process and subsequent vacuum consolidation, using the existing reinforced concrete pipe as a lost mould.

Key Benefits:

- Reliability: calculated, tested, and proven in real-life use case

- Durability: estimated lifetime 40 years

- Safe construction and installation phases

- Quickness execution in half the time

- Economic: much lower cost than traditional solutions

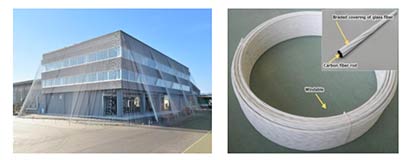

CABKOMA CFRTP STRAND ROD

Nominated for a JEC Innovation Award: Komatsu Seiren Co., Ltd (Japan) and partners Kanazawa Institute of Technology (Japan), Nagase ChemteX Corporation (Japan)

Komatsu Seiren developed a CFRTP strand rod capable of ultra-high speed moulding at low cost by in-situ polymerizing of a thermoplastic epoxy resin.

Key Benefits:

- High productivity at low cost

- High durability and high strength

- Non-ferrous, rustproof material

- Lightweight and windable

- Good processability, can be applied on-site

INNOVATIVE PULTRUDED DECK FOR STATION PLATFORMS

Nominated for a JEC Innovation Award: Solutions Composites (France) and partner Top Glass (Italy)

Innovative pultruded deck for station platforms to improve and provide safer accessibility to trains.

Key Benefits:

- Lightweight material, ease of use

- High mechanical performance, robustness

- Material savings, resulting in cost savings

- Great fire properties

- Long-lasting solution

MARINE

NEW PROCESS FOR MANUFACTURING HYDROFOILS

Nominated for a JEC Innovation Award: Multiplast Groupe Carboman (France) and partner Groupe Bénéteau (France)

Multiplast transferred wind blade building knowledge from one of its branches to create a mass production process for the manufacture of foils (one set a week).

Key Benefits:

- Reduced production cost

- Improved ergonomics for better work performance

- Waste reduction

FROM STEEL TO COMPOSITES IN A 110M-LONG RIVER CRUISE SHIP

Nominated for a JEC Innovation Award: Saertex GmbH (Germany) and partner Meyer Werft (Neptun) (Germany)

From steel to composites: Neptun and Saertex created a composite deck for a 110m-long river ship certified by the CCNR European authorities.

Key Benefits:

- CCNR approval

- 5cm less draught: longer season

- Passenger safety in case of a fire on board

- 45% weight savings

- Design freedom for the ship engineers

COMPOSITE CARGO DECKS FOR A 7000-CAR CAR CARRIER VESSEL

Nominated for a JEC Innovation Award: Uljanik JSC (Croatia)

SIEM Cicero car carrier vessel using a large number of GRP composite structures for cargo decks, saving considerable weight, reducing fuel consumption and CO2 emissions.

Key Benefits :

- Reduced fuel consumption: 4.5% or 2.1 t/day

- Increased payload: 800 tons

- Reduced production lead time

- Improved crew and cargo safety in case of a fire

- Same production cost as conventional design

RAILWAY

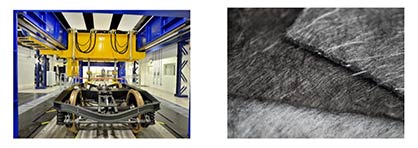

OPTIMISED LIGHTWEIGHT CARBON FIBRE BOGIE FRAME

Nominated for a JEC Innovation Award: ELG Carbon Fibre Ltd (UK) and partners Alstom Transport (UK), Magma Structures (UK), University of Birmingham (UK), University of Huddersfield (UK)

This is the first project to develop a carbon fibre bogie frame including recycled material that addresses the barriers that have prevented commercial adoption.

Key Benefits:

- Weight reduction of at least 50%

- Reduced track wear and maintenance

- Reduced global warming potential

- High-volume manufacturing technique

- Reduced capital cost of the composite solution

COMPOSITE RAIL DOOR

Nominated for a JEC Innovation Award: Penso (UK)

Penso designed and manufactured a composite rail door leaf assembly suitable for London Underground, improving the reliability and maintenance of the original aluminium component.

Key Benefits:

- Overall weight saving

- New window cassette design

- Improved durability

- Closed-cell core to prevent water ingress

- Compliant with BS 6853 Category 1A

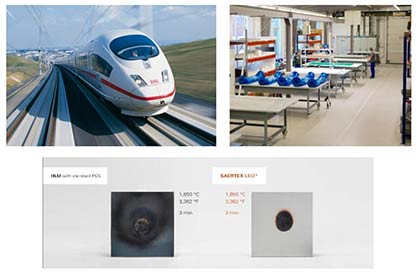

BREAKTHROUGH IN RAILWAYS: RENOVATING THE ICE TRAIN

Nominated for a JEC Innovation Award: Saertex GmbH & Co (Germany) and partners Forster System-Montage-Technik GmbH (Germany), Alan Harper Composites (UK)

Replacing plywood floor panels with Saertex Leo® GFRP panels in 66 of the prestigious ICE3 fast trains of Deutsche Bahn.

Key Benefits:

- Passenger safety: compliance with new EN 45545-2 standard

- 50% weight reduction

- Increased lifetime, high tensile strength

- Non-toxic solution

- Ease of use: vacuum infusion

SPORTS & LEISURE

PROJECT CEDRUS: ADVANCED CARBON HYDROFOIL FOR KITES

Nominated for a JEC Innovation Award: Adherend Innovations, LLC (USA) and partner Composites Universal Group (USA)

Using a patent-pending design and manufacturing technique based on optimized composite materials, Project Cedrus is the lightest, safest, most compatible, and environmentally friendly hydrofoil ever introduced.

Key Benefits:

- Reduced environmental impact

- Safety

- Low weight

- Low cost

- Compatibility

MODULAR CONSTRUCTION SYSTEM FOR A MOTORCYCLE REAR SWINGARM

Nominated for a JEC Innovation Award: BMW Group (Germany) and partners EDAG Engineering GmbH (Germany), KraussMaffei Technologies GmbH (Germany), Chr. Karl Siebenwurst GmbH & Co. KG (Germany), TUM-LCC (Germany), Automation W + R GmbH (Germany), FHG-IGCV (Germany)

Modular system for a complex-shaped carbon fibre-reinforced swingarm to individually adjust the mechanical properties at competitive cost and weight compared to metallic solutions.

Key Benefits:

- Performance-adapted parts within one mould

- Adapted load path, carbon UD tape reinforcement

- Economic large-scale production possible

- High design flexibility by injection moulding

- Good coherence with simulation and testing results

FIRST-EVER CARBON/PEI HOCKEY STICK

Nominated for a JEC Innovation Award: Schappe Techniques (France) and partners Visceral Performance Inc. (Canada), Groupe CTT (Canada), Compsult (Canada), Mat-Comp (Canada)

An advanced hockey stick (made of continuous carbon-fibre-reinforced thermoplastic materials) that delivers superior toughness/durability and on-ice performance, while being fully recyclable.

Key Benefits:

- Superior toughness / durability of the composite

- Short consolidation cycle

- Fully recyclable (hollow part)

SMART CITIES

5G SMART LED LIGHTING POLE

Nominated for a JEC Innovation Award: Exel Composites Oyj (Finland) and partners Nokia Bell Labs (Finland), Vaisala Oyj (Finland), Teleste Oy (Finland), Indagon Oy (Finland)

Smart LED lighting pole with integrated functions. A real-world use-case product that enables the development of a smart city.

Key Benefits:

- Integrated functions – enables new business models

- Ease of assembly, lightweight pole

- Longer lifetime compared to steel and wood

- Aesthetically camouflaged antennas

WET CORE POD COMPOSITE HOUSING MODULE

Nominated for a JEC Innovation Award: G12 Innovation (Brazil) & MC Materiales Compuestos (Argentina) and partners Plaquimet (Argentina), Purcom (Brazil), IS Groupe - Composite Integrity (France)

The Wet Core Pod is a composite housing module that, through industrialization, facilitates the most complex, expensive and time- consuming stage of a construction project.

Key Benefits:

- Reduce construction time, increase productivity

- Total Quality Control

- Energy save and environment friendly

INFUGREEN 810 BIO-RESIN FOR THE SEABUBBLE WATER TAXI

Nominated for a JEC Innovation Award: Sicomin (France) and partner Decision SA (Switzerland)

The InfuGreen 810 bio-based infusion resin offers the highest level of sustainable content on the market, the same performance as conventional epoxies and high-volume manufacturing capability.

Key Benefits:

- Highest level of sustainable content on the market

- Same performance as conventional epoxies

- Enables high-volume manufacturing

- DNV/GL certification

- First industrial-volume bio-epoxy infusion resin

SUSTAINABILITY

INNOVATIVE THERMOPLASTIC-MATRIX WIND TURBINE BLADE

Nominated for a JEC Innovation Award: Arkema Inc. (USA) and partners IACMI – The Composites Institute (USA), Johns Manville (USA), Huntsman Polyurethanes (USA), Sika Axson (USA), TPI Composites (USA)

The nine-metre demonstrator blade highlights new technologies to drive down the LCOE. Technologies are available for use in current wind blade manufacturing plants.

Key Benefits:

- More environmentally friendly materials / processing

- Recyclable thermoplastic blade shell and shear web

- First use of textile PAN carbon fibre in wind applications

- Overall lower cost of blade manufacture

- 100% post-consumer PET foam usage

3-IN-1 LINE FOR RECYCLED COMPOSITES MANUFACTURING

Nominated for a JEC Innovation Award: CETIM-CERMAT (France) and partner CETIM (France)

Modular line using an innovative thermomechanical process to manufacture large-scale panels from composite or plastic waste and for hot-stamping parts from these panels.

Key Benefits:

- Modular, flexible production line

- Production of high-performance recycled composites

- Cost effectiveness

- Technologies adapted to SMEs

LOOP 650: A SUSTAINABLE CRADLE-TO-CRADLE COMPOSITE SAILING BOAT

Nominated for a JEC Innovation Award: GS4C srl (Italy) and partners Entropy Resins (Spain), Isomatex (Belgium), Diab (Sweden), GIVIDI Fabrics (Italy), Cormatex (Italy)

Sustainable, zero-landfill cradle-to-cradle industrial composite manufacturing technology demonstrator.

Key Benefits:

- Industrial ready

- Cradle-to-cradle recycling

- Zero-landfill manufacturing

- Low embodied energy