#ITMA-Asia + CITME-2016

Mayer & Cie. at ITMA Asia + CITME

Insolvency proceedings for the circular knitting and braiding machine manufacturer Mayer & Cie. were opened on December 1, 2025. Immediately following the opening of proceedings, the complete cessation of business operations was initiated. Most employees were subsequently given notice effective the end of February 2026. The production of the remaining orders in the circular knitting segment is expected to be completed by the end of the month. As early as December 2025, Mayer & Cie.’s braiding machine division was sold to an Italian investor.

Mayer & Cie., the long-established German manufacturer of circular knitting and braiding machines, will cease operations after its international search for an investor ended without success. The company, based in Albstadt-Tailfingen, had been undergoing insolvency proceedings in self-administration since its filing on 23 September 2025. As Schwarzwälder Bote reports, the insolvency court has now formally opened the proceedings, triggering the decision to wind down the business in an orderly process.

On 23 September 2025, Mayer & Cie., a manufacturer of circular knitting and braiding machines in Albstadt, filed an application for the opening of insolvency proceedings in self-administration at the Hechingen District Court.

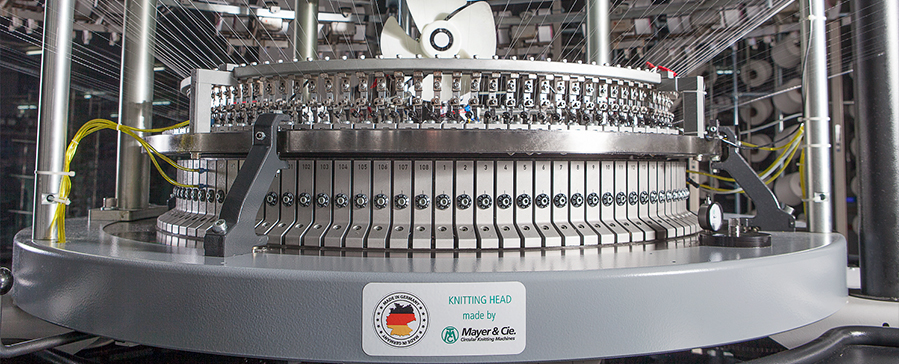

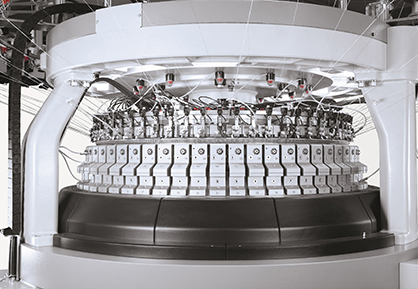

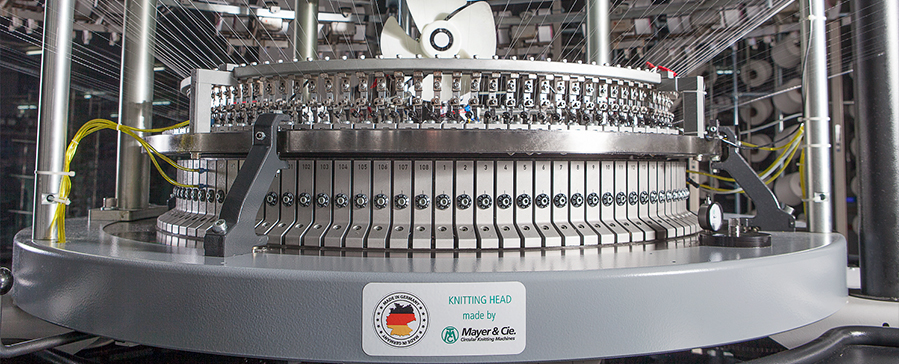

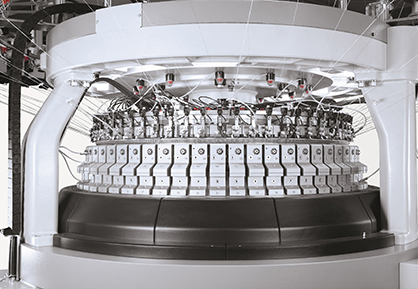

Mayer & Cie. will participate in ITMA Asia from October 28 to 31, 2025, which takes place in Singapore. Visitors will find the manufacturer of circular knitting machines and braiding machines in Hall 5, Stand D 301. At its booth, the company will be showing a new circular knitting for jacquard fabrics - the OVJA 2.4 EC II - and will provide an overview of its digital and smart solutions. Another focus is on the machines of Mayer & Cie's "Performance Line": circular knitting machines, which are the most efficient solution in their respective classes.

With the European Commission’s decision to provisionally apply the EU–Mercosur Interim Trade Agreement, a process spanning more than 25 years now moves decisively into its implementation phase.

Selenis, a global leader in high-performance specialty polyesters and part of the IMG Group, has announced a transformational expansion of its industrial headquarters in Portalegre, Portugal. This strategic investment is set to double the site’s production capacity by the third quarter of 2027, significantly accelerating the industrial scale-up of bio-based, medical-grade, and circular co-polyesters.

Independent laboratory testing has confirmed that Milliken fabrics used in the manufacturing of firefighter turnout gear contain no detectable PFAS, based on third-party analysis conducted by Forever Analytical, an independent laboratory specializing in screening products and environmental samples for the presence of per- and polyfluoroalkyl substances (PFAS).

Following the conclusion of Heimtextil last month, the flagship fair in Messe Frankfurt’s global home and contract textiles portfolio, Intertextile Shanghai Home Textiles – Autumn Edition will return 18 – 20 August 2026 at the National Exhibition and Convention Center (Shanghai). Building on the momentum generated in Frankfurt, the Shanghai fair will reinforce its position as the foremost home and contract textile platform in Asia – successfully bridging the gap between East and West, and connecting global product trends, supply-chain shifts, and buyer demand in one marketplace.