#Weaving

Stäubli will share its historic know-how of the textile industry in a booming market at CAITME 2024

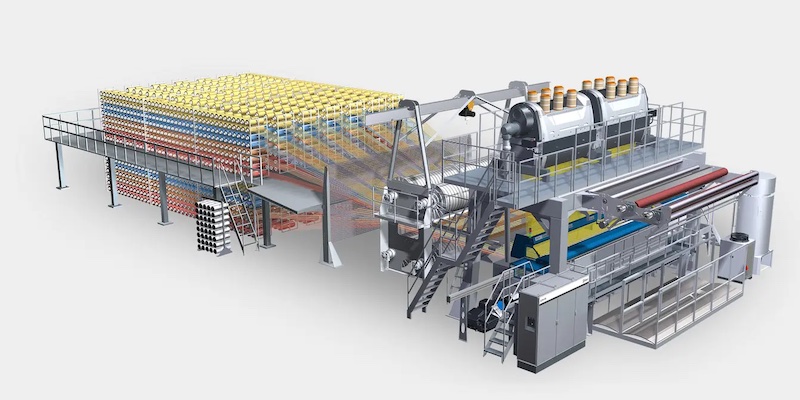

Stäubli’s cutting-edge weaving technology is invaluable to many industries, including fashion, home textiles, flooring, automotive, safety & protection, and manufacturing. Stäubli has been developing and producing high-quality systems for the weaving industry for over a century and holds a strong market position in textile machinery, a position earned through the continual pursuit of customer satisfaction.

Carpet weavers will discover about the extremely flexible ALPHA 580 UNIVERSAL carpet weaving machine, which enables carpet weavers to swiftly react to changing customer demands and market needs.

Visitors will discover how automated weaving preparation can optimize their overall process with

+ Smooth weaving start-up thanks to the TIEPRO warp tying machine offering easy use and ensuring perfectly tied warps.

+ SAFIR PRO automatic drawing-in machines, equipped with state-of-the-art AWC 2.0 technology, interpreting measured data through image processing and data analytics, using advanced algorithms and software and high-performance processors. AWC 2.0 gives mills expanded capabilities to produce innovative, outstanding, and unique designs.

Visitors will learn more about Stäubli’s renowned shedding solutions – including cam motions, dobbies, and the Jacquard machine PRO series, featuring:

+ Dobby and cam motion ranges for high-speed operations. The dobby ranges, combined with the new e32g transmission, are a must-have for frame-weaving mills that demand maximum productivity. The S3200 dobby machines feature a fully integrated cooling system with optimized and regulated thermal control, enhanced temperature management, a new lubrication system, and the capacity to handle heavier loads.

+ The Jacquard machines from the PRO range features the innovative MX PRO module, controlled by NOEMI electronics architecture and the TC8 controller. This energy-efficient Jacquard installation promises weavers outstanding reliability and ease of use.

Finally, thanks to continual and focused research, Stäubli is in the position today to offer weaving machines for all types of technical textiles, especially heavy industrial textiles and reinforcement fabrics for lightweight applications.