#Weaving

Mono wire healds from Groz-Beckert: Optimized for application and environment

From RONDOFIL to Jacquard

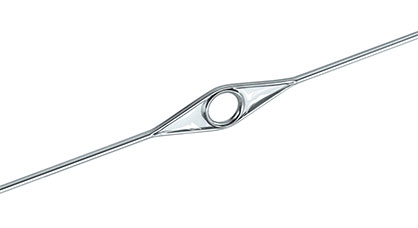

Both Groz-Beckert RONDOFIL healds and Groz-Beckert Jacquard healds are made from a single wire. This provides a perfect surface for even the finest warp threads. The surface quality of mono-wire healds is also advantageous for very high row densities of warp threads: High-quality fabrics produced with maximum efficiency are the result.

The mono wire healds from Groz-Beckert are also characterized by the fact that their thread eye, also known as mail eye, is not twisted-in and soldered, but glued. Compared to the use of twin wire healds, the thread surface is therefore protected even more and damages to the warp yarn due to material fatigue and corrosion are prevented. Another advantage of the glued thread eye is that no lead-containing solder must be used for fastening, which makes the healds more environmentally friendly and resource-saving.

The advantages of Groz-Beckert mono wire healds at a glance:

1. Surface is gentle on thread

2. Made from mono wire for high densities

3. No soldering tin used

4. Made from stainless steel

5. Suited for any yarn

6. Highest production accuracy

7. Customer-specific specifications available

REACH compliant and environmentally friendly

The avoidance of lead-containing soldering tin in the manufacture of healds offers advantages across the board. In contrast to other competitor products, the mono wire heald does not contain any lead and is therefore not harmful to health or the environment. Precautions that are required when handling SVHC lead, such as special skin protection, are therefore not necessary. This means that mono wire healds from Groz-Beckert are also REACH-compliant and thus help to meet compliance requirements with regard to the use of chemical substances.

Groz-Beckert service

Buyers of mono wire healds from Groz-Beckert who need a REACH certificate for compliance reasons can contact their Groz-Beckert representative who will be happy to prepare this for them.