#ITMA 2019

Environmentally-aware and efficient: DORNIER to present its newest “Green Machines” and an expanded service offering at the ITMA

When the subject of sustainability is raised, businesses are often called upon to take the lead. Lindauer DORNIER is doing precisely that, as enshrined in one of our seven guiding principles: “We strive to design and manufacture our products so that they are as safe and environmentally compatible as possible.” This commitment was formulated by the company founder, Peter Dornier over three decades ago.

Our presence at the upcoming ITMA exhibition – the International Textile Machinery Exhibition – is further proof that sustaina- bility is not just a passing fashion at DORNIER, but rather the foundation and result of a long-term corporate strategy. At this event, under the banner theme of “The Green Machine” we will present the latest machines and lines, “Made in Germany” for the sustainable, efficient manufacture of clothing, home textiles and technical fabrics and flexible, economical production of high-quality composite semi-finished materials.

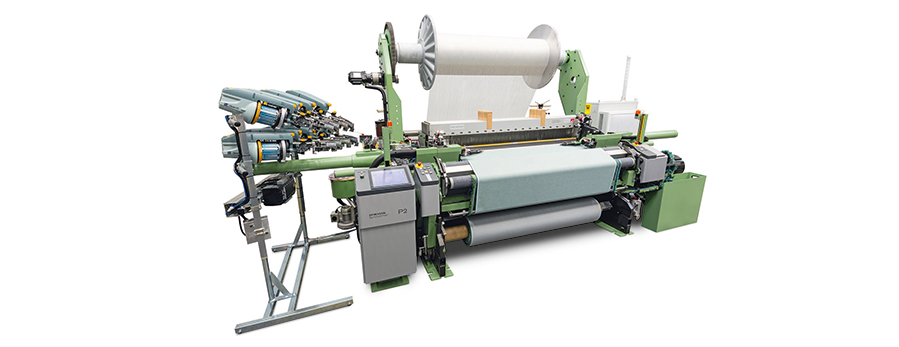

World premiere of the new rapier weaving machine P2

Highlights include the new rapier weaving machine P2, which will be presented in its standard configuration for the first time in Barcelona. It combines the strengths of the P1 All-rounder with many innovations to equip the weaver optimally for the future. “We didn’t reinvent rapier weaving, but we improved every major aspect of the process”, says Thomas Laukamp, DORNIER’s Head of Advanced Technology Development Weaving Machines. Accordingly, with improved shed geometry and a more rigid frame, greater productivity, maintenance-free operation and optimized positive center transfer movement, the P2 rapier weaving machine offers the highest flexibility and process reliability available on the world market.

The new machine structure with clearly defined primary and auxiliary modules represents a further advance. “The modular design and clear interfaces between the machine modules make conversion and expansion work simpler”, explains Laukamp. He adds that this translates to greater investment security for the weaver, because the P2 can easily be adapted for proces- sing different yarns for clothing, domestic and technical textiles as well as high-quality composite semi-finished materials. So the weaver can respond faster to unpredictable market developments. “Who knows what orders weavers will have to deal with in five years” said Laukamp, who sees DORNIER as a solution provider.

Besides, the P2 was the perfect example of a technology approach conceived for total sustainability: Not only did the ultrafine precision fabrics it produced keep air and water clean or lter exhaust gases, the machine itself was designed for sustainability: “The resource-saving operating principle and long service life of the P2 make it a truly ‘Green Machine’”, says Head of Advanced Technology Development Laukamp.

Future-oriented: The encapsulated air-jet weaving machine

On the subject of air-jet weaving, DORNIER will exhibit an encapsulated air-jet weaving machine. This solution is designed to bring different, individually controllable climate zones into the production workshop for the first time: This means that each weaving machine can be run in its own climate, adjusted to create the ideal conditions for the respective manufacturing process, regardless of the heat and humidity in the rest of the production workshop.

This approach too makes for the greatest possible flexibility in accepting and completing orders, since it is then possible to process different fibers ranging from wool to glass simultaneously in the same workshop. The lower levels of noise, dirt and mechanical vibration that prevail as a result of the encapsulation also make the fabric manufacturing workstations safer and more comfortable - a convincing argument for recruiting young employees and experienced technicians.

24/7 online shop for original parts: The new myDoX® customer portal

The new myDoX® customer portal will also be presented at the ITMA. Based on the latest database technology, the portal adds digital order management to the personalized technical, installation and maintenance service for which DORNIER is known. It will provide an online shop with permanent availability for original parts (DoXPOS – Parts Order System) for all product lines. Remote maintenance and networking of weaving machines – to improve run characteristics, for example – will also be possible in future via myDoX®.

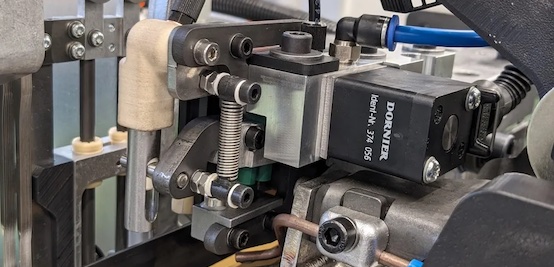

More ITMA highlights from DORNIER: The new color selector and feed system DORNIER DisCoS (DCS) for rapier weaving machines, enabling more efficient processing of up to eight colors; the DORNIER Weft Saver (DWS) weft saving device which enables weaving without a left catch selvedge, reducing weft; the double weft rapier heads DORNIER DoPPIO with free color transfer and parallel weft insertion.