#Weaving

Automated fabric inspection with the USTER brand

Taking the successful EVS fabric inspection systems into its portfolio, USTER will seek to expand the scope for automated fabric quality assurance. Its filament yarn tester has already made an impact in technical textiles markets, and this sector will also see USTER explore further applications for its fabric inspection systems, starting with the forthcoming Techtextil North America exhibition.

In filament yarn production, the USTER® evenness tester is now almost as well-established as in cotton spinning. The distinctive grey and red livery of the instrument today is a familiar sight in the laboratories of technical textile yarn manufacturers, acknowledged as essential equipment over the past six decades. In its latest version, the USTER® TESTER 6 C-800 drives global standards – and its new capacitive sensor gives filament yarn producers the power to guarantee right-first-time quality.

Automated fabric inspection

USTER’s product portfolio in laboratory testing is well known, not so the competences in other areas of technical textile processing. At Techtextil North America 2019 USTER introduces its newly-integrated systems for automated fabric inspection. Although the USTER name may not yet have the impact in fabric manufacturing as in other sectors, its range of inspection technology now being presented is class-leading, backed by 28 years’ experience.

This new offer is based on USTER’s acquisition last year of Elbit Vision Systems (EVS), the Israel-based pioneer in automated optical inspection equipment. Now incorporated within USTER, the EVS products are part of a comprehensive textile quality monitoring and control offering, from fiber to fabric.

Multiple technical textiles applications

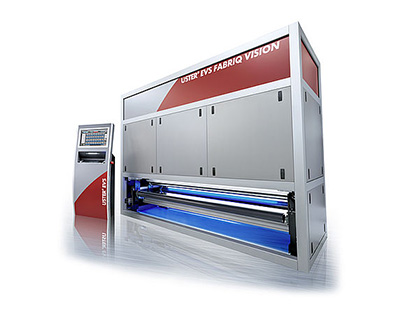

EVS technology is applicable to wide-ranging fabric types and end-uses, including numerous specific and diverse segments of technical textiles. Visitors to previous Techtextil North America shows have already been able to view EVS monitoring and fabric quality assurance systems since 2006. The latest developments to be featured at the upcoming show (Booth 1429) in Raleigh, North Carolina display the classic USTER design and carry the new product designations: USTER® EVS Q-BAR, USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE.

In these demanding and often sensitive applications, materials must generally be lightweight, durable and sustainable, with secured and consistent quality as the absolute prerequisite. Says John Belew, Vice-President Sales at Uster Technologies Inc., USA: “Among international experts from architecture, the automotive industry, medicine, the fashion industry or personal protection we want to continue to spread the word about on-loom inspection. Together with the suppliers to these industries, we aim to find new applications for our finishing systems.”

Developing unique customer experiences

Some EVS customers have been enjoying the advantages of automated fabric inspection for more than 20 years. Over that period, ongoing development of the systems has kept pace with their needs. The commitment to strict quality control – eradicating fabric defects and even the slightest deviations in color shade – has created and developed unique customer experiences. Mills installed fabric inspection systems on equipment such as tenter frames, coating lines and sanforizers. Customer satisfaction with EVS was enhanced by measurable benefits across KPIs: production efficiency, increasing yield, and lower labor costs – adding up to higher profitability.

“Long-term customer relationships show that the systems we offer continuously develop in parallel with the need of the users. We want them to produce a better product for their market – and no less,” says Belew. “At Techtextil, we will show that trusting USTER means no compromises in quality with automated fabric inspection installed.”