#Textile processing

The Groz-Beckert Needle Finder – from seam to needle

From the seam to the needle – Find the right sewing machine needle for your product

The many variables also influence the choice of needle. Not only must the correct needle system be selected, but the needle size and point shape must also be adapted to the material being sewn. This often makes choosing the right needle difficult.

The path to the right needle

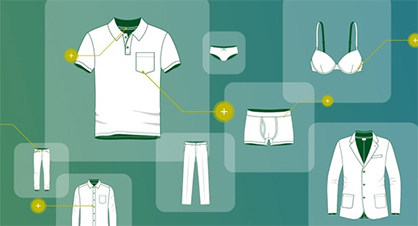

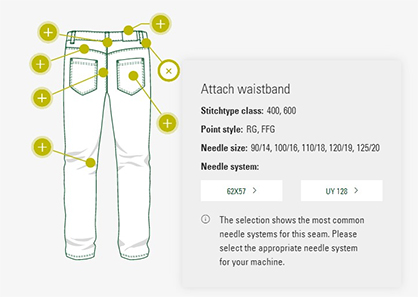

With the “Needle Finder”, Groz-Beckert offers an interactive tool to help you select the right needle. Various product examples with different seams are displayed for this purpose. Selecting a seam displays details of the application, such as the stitch type class. You will also receive recommendations tailored to the product and seam with regard to needle point and needle size. In addition, the most common needle systems used for the chosen seam are suggested.

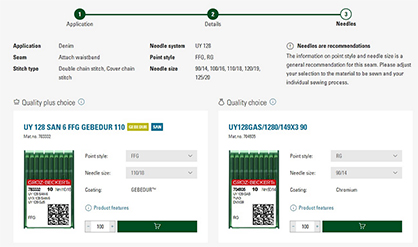

Once the needle system suitable for your machine has been selected, you will be taken directly to the order function. There, you can choose from the recommended needle point shapes and needle sizes. In many cases, the Needle Finder will suggest a different version in addition to the standard needle. This could be a special application needle that has been specially developed for sewing the chosen product, for example, or a needle with other special features that offers additional advantages for the selected application.

The Needle Finder is integrated in the Customer Portal Sewing. It can be found on the homepage directly under the “Top products” category. To use the order function, you must be registered with a customer account.

Go to the needle Finder:

https://portal.groz-beckert.com/germany/sewing/en/needle-finder

The Needle Finder functions at a glance:

- Support with selecting the correct needle

- Wide range of product and seam examples

- Display of the most common needle systems for the seam

- Recommendations for needle size and point shape, adapted to the relevant seam and material

- Suggestions for needles specially adapted to the application (e.g. special application needles)

- Direct order function

- Optimized for display on mobile devices

- Available worldwide and in 14 languages

The Needle Finder is constantly being further developed and a wide range of products added to cover all applications as comprehensively as possible.

Additional support from our sewing and joining service

Your contact person at Groz-Beckert will also be happy to answer any questions you may have about selecting the right needle for you or placing needle orders.

Our sewing and joining service offers additional services for process optimization for individual needle recommendations or to provide support with any application problems.

In compliance with globally uniform standards, our application technology experts create individual error analyses and problem solutions and develop a needle recommendation specially tailored to your application. You will receive a suitable tailored assessment report depending on the service package.

Information on our sewing and joining services is also available here:

https://portal.groz-beckert.com/germany/sewing/en/needle-finder

Other functions and benefits of the Customer Portal

In addition to the Needle Finder, the Customer Portal offers additional functions and advantages:

- Product catalog with access to all products from the range of sewing and shoe machine needles

- Quick and easy product search function

- Wide range of product details and technical information

- Customer account with access to all orders and invoices

- Personal dashboard with important key figures

- Various ordering options (Excel upload, order templates, scan function)

- Wide range of information on sewing machine needles and the sewing process

- Optimized for use on mobile devices

Go to the Customer Portal:

https://portal.groz-beckert.com/germany/sewing/en/startpage