#Techtextil 2024

BASF now offering polyamides for the textile industry according to Recycled Claim Standard (RCS)

- Certification of PA6 and PA6.6 Ccycled® products for textile applications

- Expansion of the broad polyamide product portfolio according to ”Choose to reduce” approach

- BASF presents Ccycled portfolio and other sustainable PA solutions at Techtextil trade fair in Frankfurt

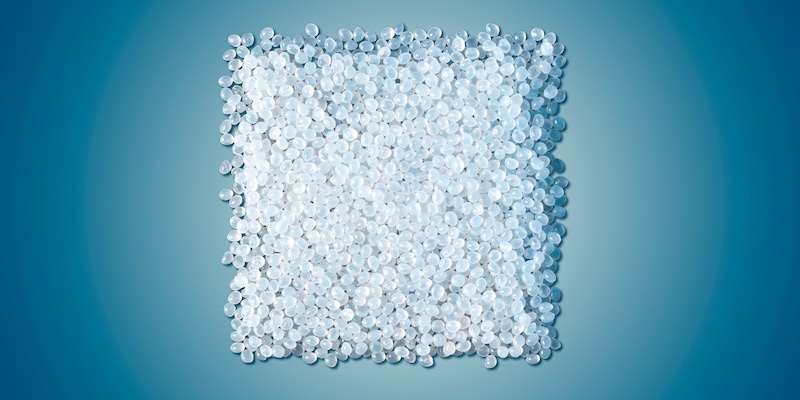

The production of Ultramid Ccycled is based on the chemical recycling of plastic waste that is difficult to recycle, such as used tires. With ChemCycling®, the recycled raw material is fed into the BASF production network at the beginning and assigned to the Ultramid Ccycled products using a mass balance approach.

BASF's Ccycled portfolio is already certified according to ISCC PLUS and REDcert2. To promote the acceptance and spread of chemical recycling in the textile industry, BASF has been working with the standards of Textile Exchange since 2020. As one of the leading non-profit organizations in the field of recycled raw materials certification for the textile industry, Textile Exchange has established the RCS certification process. “We are proud that we can offer our Ultramid Ccycled with this certification for the textile industry and thus expand our product portfolio even further,” said Dr. Dominik Winter, Head of Business Management Polyamides Europe at BASF.

By offering RCS*-certified PA6 and PA6.6 Ccycled products, BASF is expanding its broad polyamide portfolio of sustainable solutions for the textile industry. In a “choose to reduce” approach, customers can choose between products whose production saves fossil raw materials through the use of recycled materials, thereby reducing their carbon footprint. The quality and performance of the products remain unchanged.

BASF will be presenting its Ccycled portfolio for the textile sector to customers and partners at Techtextil, the leading international trade fair for technical textiles and nonwovens. It will take place from April 23 to 26, 2024 at Messe Frankfurt. The BASF stand will also feature loopamid®, the first circular PA 6 based entirely on textile waste, and Ultramid® Biomass Balance (BMB), a drop-in concept that enables the use of biowaste raw materials in product manufacturing.

* by means of a mass balance approach taking into account the "Alternative Volume Reconciliation (VR2) Policy"