#Techtextil 2024

DITF honored with Techtextil Innovation Award for research on self-cooling textiles

The research work, carried out in collaboration with Schill+Seilacher GmbH, was financially supported by the Ingeborg Gross Foundation as part of Lea Zimmermann's doctorate.

Due to climate change, the need for cooling energy in buildings has increased significantly. Previous cooling systems such as air conditioning systems are based on thermodynamic cycles that consume a lot of electricity and release waste heat and carbon dioxide into the environment.

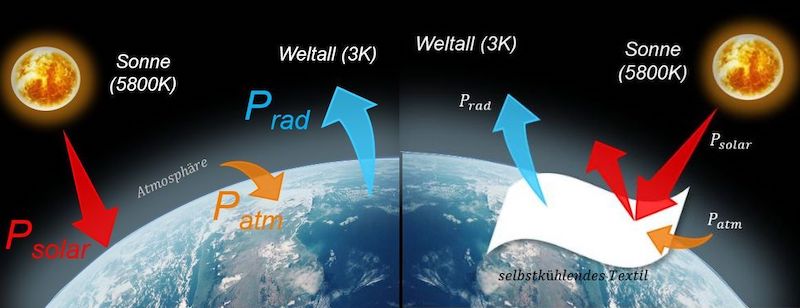

Technologies such as radiant cooling offer a sustainable and energy-free solution. They use the wavelength ranges of the atmosphere that are permeable to electromagnetic radiation to emit thermal radiation into colder space. Radiative cooling is a ubiquitous process in which a surface facing the sky loses heat through thermal radiation. The largest object that emits heat through radiative cooling is the Earth itself. The cooling effect can be seen, for example, on clear mornings through the formation of frost and dew.

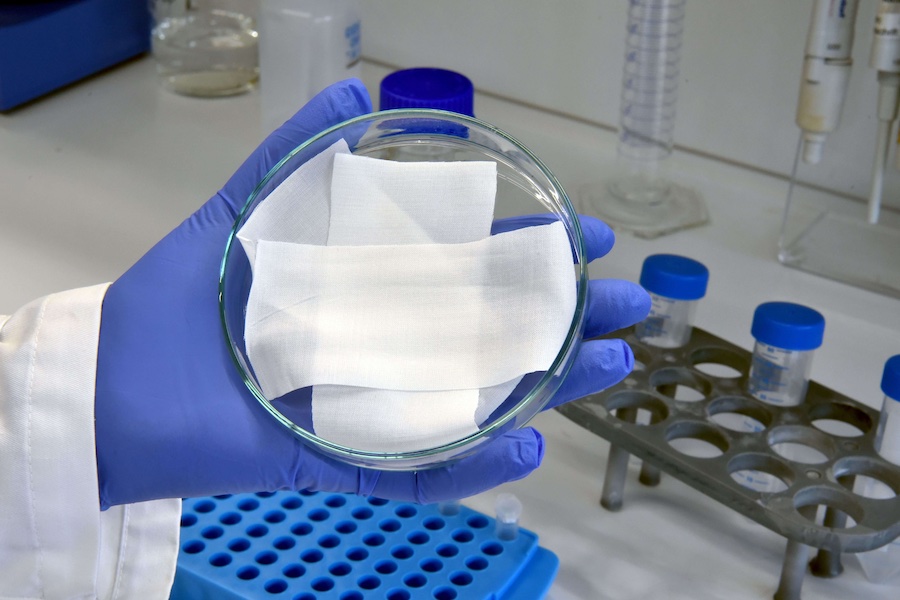

In order to utilize this principle, a resource-saving coating formulation for technical textiles was developed at the DITF which has two special properties: firstly, this coating reflects sunlight with high efficiency, preventing the textile from absorbing energy and heating up in the process. At the same time, this coating has a high radiation effect in the mid-infrared range. As a result, the thermal energy of the coated textile radiates into the cold outer space and the textile cools down. These two properties ensure that the coating does not heat up, but actually cools down.

The textile coated with this enables cooling down to 2°C below ambient temperature even during the day in full sunlight, while the uncoated reference textiles heat up strongly with a temperature gradient of up to 20°C. The coating is sustainable, easy to apply and scalable. The matrix material has high UV and weathering stability and is water-repellent.

DITF would like to thank the Ingeborg Gross Foundation for the doctoral scholarship.