#Techtextil 2024

BRÜCKNER comes to Techtextil to show 75 years of tradition and innovation

Industrial textiles

In the field of coating and finishing industrial textiles, the world market leader offers the right unit for almost every process. Whether full-bath impregnation for aqueous media, one-sided full-surface or dot application of latex and acrylate pastes, foam or paste application via various roller and squeegee systems or the application of laminating adhesive - BRÜCKNER has a solution for every process. Numerous customers worldwide are very satisfied with their BRÜCKNER lines for coating or laminating abrasive cloth, airbags, roof membranes, blackout material, billboards, geotextiles or tarpaulins. In addition to the application units and coating lines, the portfolio also includes the right drying systems.

Nonwovens

These include, for example, the thermofusion ovens of the SUPRA-FLOW product line, which are mainly used in the nonwovens industry. Among other things, high-loft nonwovens for mattresses, insulation, comforters or upholstery, as well as lightweight nonwovens for the hygiene industry such as ADL nonwovens, topsheets or backsheets can be finished on the air-through thermofusion ovens. BRÜCKNER also offers air-through dryers for scrubbing nonwovens, kitchen towels, operating table covers, paper napkins and feminine hygiene products as well as high-speed spunlace lines for wipes, wet wipes and wet laid nonwovens. The POWER-FRAME stenter with proven split-flow technology is used for the thermal treatment of needle felts, high-temperature filters or geo- and agro-nonwovens. It is usually at the heart of the finishing process for classic garment textiles and is also ideal for drying and heat-setting after digital printing.

Floor coverings

Discover our expertise in coating, laminating and drying textile floor coverings for yourself. The DUO-THERM dryer deserves special mention here. It is the perfect solution for thermal treatment processes that require temperature separation between the upper and lower air. Like all BRÜCKNER lines, it can be heated with different media: Gas (direct or indirect), thermal oil, steam in low or high pressure versions, electric heating or various hybrid versions. Just recently, a BRÜCKNER line for drying single-sort floor coverings was equipped with a fully electrically heated DUO-THERM dryer. By operating this dryer with green electricity, the long-standing BRÜCKNER customer was offered the possibility of CO2-neutral production of tufted carpets.

Textile expertise made easy

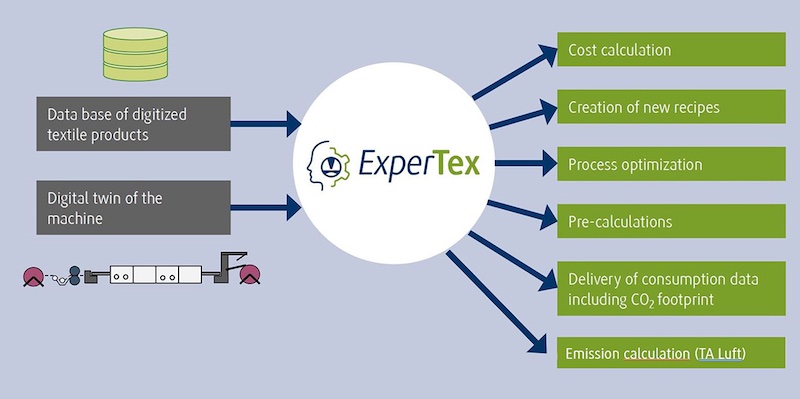

The new ExperTex simulation tool is a calculation program that makes it possible for the first time in the world to digitally simulate textile drying, heat-setting and curing processes. In addition to the pure process simulation, a comprehensive calculation of consumption data (e.g. electrical and thermal energy required, production costs or the CO2 footprint) is integrated. The active process is automatically perfected using an optimization menu. The innovative algorithm simulates, analyzes and optimizes the entire range of possible setting parameters depending on the specified process, either for maximum production output or to reduce energy consumption. The new ExperTex program is browser-based and intuitive to use.

Visit BRÜCKNER at the TECHTEXTIL in hall 12.0, stand B54.