#Techtextil 2024

Multi-directional sewing at Texprocess 2024

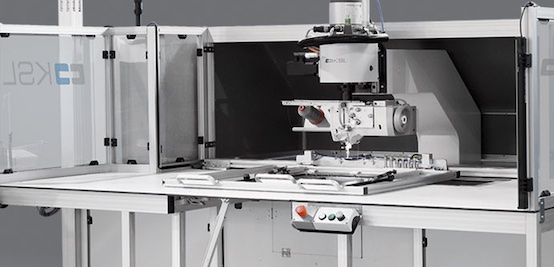

A highlight of their offerings is the unique CNC solutions provided by KSL, incorporating both single and double-needle technology for lockstitch and chainstitch applications. Their CNC technology boasts a maximum sewing speed of up to 2,800 stitches/min and can achieve stitch lengths of up to 12 mm, depending on material and application.

At the TEXPROCESS 2024 exhibition, PFAFF INDUSTRIAL and KSL are set to showcase their cutting-edge CNC systems, featuring the latest AI-based ONLINE VISION SYSTEM for guided sewing. The KL 311 system utilizes this technology to control and optimize seam patterns in real-time, stitch by stitch, particularly beneficial when sewing partially perforated leather. Positional inaccuracies are swiftly detected and corrected, ensuring top-notch quality while minimizing waste. Similarly, the KL 301 system leverages the intelligent VISION SYSTEM to aid in the precise positioning of small parts, enhancing productivity and relieving operators.

In collaboration with Sonotronic, PFAFF INDUSTRIAL presents a dynamic duo for small leather goods production at the Frankfurt exhibition. Utilizing the PFAFF 3690 CNC machine for sewing and the Sonotronic iSONIC ECO TM machine for embossing, visitors can witness the live production of small leather key rings, showcasing the seamless integration of sewing and finishing processes.

These innovative solutions, spanning the Garment, Industrial, and Welding sectors, will be on display at Hall 9.0, Stand no. B22, B26, B30, C11 in Frankfurt. Visitors are encouraged to explore the AI-based ONLINE VISION SYSTEM for Guided Sewing firsthand and take advantage of a complimentary day ticket to the fair by contacting PFAFF INDUSTRIAL and KSL.