#Textile processing

CISMA 2023 in Shanghai - SGG-Group presents latest processing technology

PFAFF INDUSTRIAL will present new, strong products at CISMA. For example, the German machine manufacturer will be showing its new PFAFF 3834 programmable sleeve setting machine. Sewing in sleeves with a tailor’s touch”. For the new PFAFF 3834 a thread tension control has been developed that automatically adjusts the thread tension to the material thickness currently being handled. The material thickness detection and real-time adjustment (360° monitoring) feature ensures optimum stitch formation, even when sewing over cross-seams and interlinings. By using the roller presser (running close to the needle), the material can be worked in with pinpoint accuracy. Optimal work with a clear view of the sewing material is assured. The PFAFF 3834 guarantees smooth seams and even stitch formation, especially when sewing sensitive and difficult fabrics.

With the PFAFF 3588 Cargo, PFAFF INDUSTRIAL presents a machine for efficiently applying non-prefolded cargo or bellows pockets in the areas of work clothing, streetwear and military clothing. The machine is unique on the market for its very high production output using the fully overlapped working method as well as its consistently maximum sewing speed (maximum 4,000 rpm) without speed reduction in corners or bars. Depending on the parts set, the shapes "Cargo one-sided", "Cargo double-sided", "Cargo L-Shape" and "Cargo U-Shape" are possible.

PFAFF INDUSTRIAL will be demonstrating reproducible thread tension (via manometer) on the PFAFF 5483-H-650/02. This special airbag setup sews the tightest 3-needle chain-stitch seams with a minimum needle gauge of 2.4 mm. The PFAFF POWERLINE 2545 unison feed machine and the PFAFF 1591 electronic shoe post machine are equipped with new, reliable thread trimmer for short thread ends (5 mm). The thread trimmer enables more efficient working without manual re-trimming of the thread.

In the "welding" section, the new PFAFF 8333 has its "Asian premiere".“. The new taping machine PFAFF 8333 is a solution for a continuous seam sealing. The new 3-D axis nozzle position of the new machine now provides the last missing link for unique process control. The PFAFF 8333 is the first machine in the world, that really allows all relevant determining factors to be pre-set to certain welding programs. The changeover from one application to another can be done by just pressing a button. No tools, no guessing, no uncertainties. And no experienced operators or technicians needed. Just plug and play.

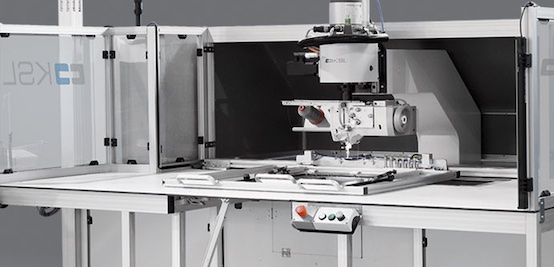

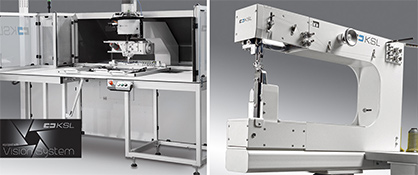

KSL will present the CNC sewing unit KL 311 (+ VISION SYSTEM) with 360° rotating sewing head and a template with a sewing area of 1.000 x 600 mm. During the sewing process, the intelligent VISION SYSTEM compensates for tolerances which have been developed. These arise due to the shrinking of materials and tolerances, including during the punching of perforations. Specifically, the VISION SYSTEM compares an image of a master example with the image of the piece mounted in the sewing template. By means of individual measurement points, the entire seam pattern is automatically corrected within the sewing programme. Process reliability is significantly increased, waste is reduced. KSL is the market leader in CNC units with the largest modular system (unique: the units are also offered as a two-needle solution with chain stitch and lockstitch). They guarantee the best sewing results in multi-directional sewing, even in highly-difficult, complex applications.

With the KL 627 KSL will be showing a chainstitch post-bed machine with a very small post for an easy handling of voluminous fabrics. An exceptionally high seam quality for decorative and topstitching work in the visible area characterises the machine. It effortlessly processes material thicknesses of up to 5 mm.

The large, motivated team of the ShangGong group is looking forward to your visit!