#Sustainability

Cone Denim introduces first solar panel installation at mill in Jiaxing, China

“This project is a great accomplishment for Cone towards our sustainability efforts,” stated Cone Denim Vice President of Manufacturing, Brad Johnson. “The solar panel installation demonstrates our commitment to continued innovation across our manufacturing facilities and platforms to reduce greenhouse gas (GHG) emissions.”

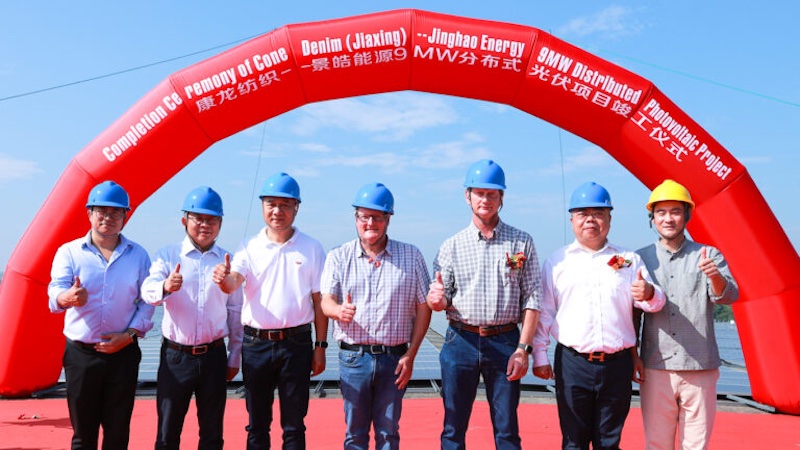

Johnson, alongside other members of the Cone Denim Jiaxing team, announced the official launch of the installation through a ribbon-cutting ceremony held on October 18. The celebration marked the first solar panel installation for Cone, and the fourth overall for its parent company, Elevate Textiles®.

The solar panel initiative will generate 9 MWH of electricity annually. Johnson estimates that this new clean energy source will provide a 17% reduction in the plant’s annual GHG emissions.

“This launch provides Cone Denim the opportunity to scale our efforts on clean energy and carbon reduction, all on-site in Jiaxing,” added Johnson. “By implementing this on our industrial site, we are preserving the natural landscape without requiring any additional surrounding land resources.”

The solar panel project efforts follow Cone’s recent announcement of its commitment to reach its 2030 sustainability goals. The commitments, set by parent company Elevate Textiles, are validated by the Science Based Targets Initiative and state a target for a 46.2% reduction in Scope 1, 2, 3, and GHG emissions. The company also has an ambition to attain 100% renewable electricity by 2030.

“The installation, alongside our other efforts like Zero Liquid Discharge at our plant in Parras, Mexico, proves our efforts to maintain our reputation as a sustainable supplier committed to trust, traceability and transparency,” stated Johnson. “With the solar panel addition, we hope to serve as a leader in sustainable offerings and innovations, while continuing to inspire change across the industry.”