#Spinning

Spotlight on polycondensation systems and precision metering pumps

The basis for high-quality yarn is homogeneous melt. Producing precisely this is the task of the high-end Oerlikon Barmag polycondensation systems for fiber-grade and bottle-grade polyester melt and granulate.

The benefits of operating an in-house polycondensation system are plain for the yarn manufacturer to see: in addition to being independent of other granulate manufacturers, short-term price fluctuations within the raw materials market and the influence on the quality of the raw material, it is above all the added value that is most likely to result in higher profits.

Oerlikon Barmag offers all process steps from a single source – from supplying the terephthalic acid, the polycondensation system and the spinning plant all the way through to the texturing equipment. Optimum coordination of the individual production steps and system parts is guaranteed as is the superlative product quality and the tremendous efficiency of the production – from the melt to yarn.

Pumps for all cases

Oerlikon Barmag pumps are deployed in numerous challenging processes within the chemical, plastics, dyes and lacquers industries and in PUR applications. The requirements for challenging processes in the chemical industry are extremely high. One the biggest challenges is metering poorly-lubricating media. With the GM and GA ranges and the corresponding components, Oerlikon Barmag supplies veritable all-rounders for numerous applications. The high-speed pump in particular fulfills the expectations of the chemical industry with its sealed product space.

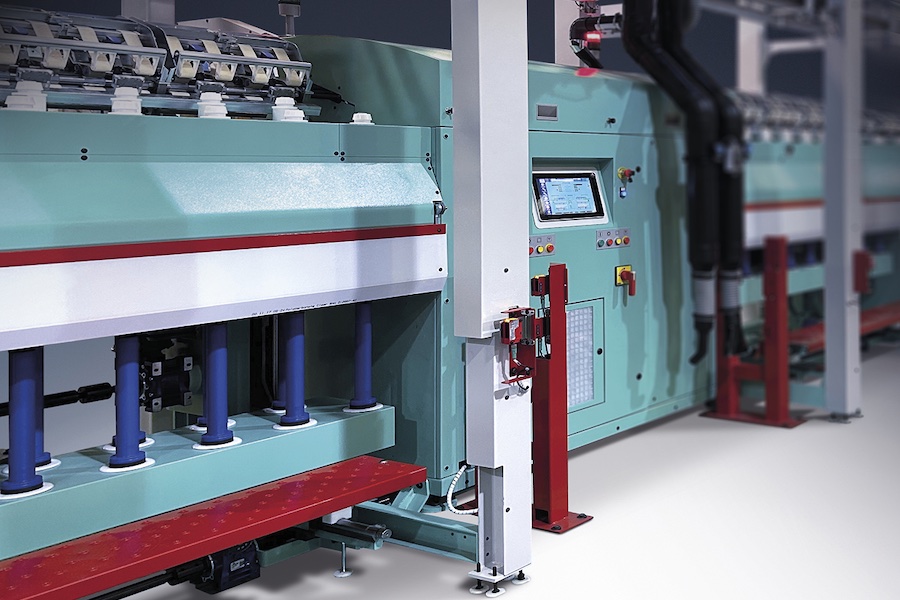

Pic: Planetary pump

High-speed metering pump meters poorly-lubricating media

The new Oerlikon Barmag high-speed metering pump has been especially developed for metering poorly-lubricating media. “The high-speed pump is particularly advantageous in the chemical industry, which conveys aggressive acids”, reports Thorsten Wagener, the salesman responsible for industrial and chemical application pumps at Oerlikon Barmag.

The main advantage of the pump is the sealed product space. The space within the pump that comes into contact with the media is therefore limited to the area around the gears. The external, ball-bearing support points in the high-speed pump are externally lubricated, hence ensuring that the product to be metered is not damaged as a result of poor lubrication. This ensures that the pump is extremely durable.

Furthermore, the enlarged speed range (30 - 500 rpm) permits a large application range for which several pumps of varying sizes have had to be used to date. This cuts back on conversion times, while simultaneously reducing spare parts inventories. With its low weight of 1.4 kg, the compact pump (ø65mm) promises both considerable space savings and less wear on the machine.

The pumps in the GM and GA series provide precision metering with low-pulsation feeding of the conveying medium. The multi-stage GM pump conveys low-viscosity media (i.e. 250 bar, 100 mPas) even under high pressure and in the most challenging conditions. The square design from the proven GM series is the standard pump for many metering tasks. The development of the multi-stage pump expands the applications range for the GM series considerably. The round 2-stage GM pump has been developed especially for use in high-pressure technology. It masters the particular challenge of conveying small throughputs with low viscosities. The pumps is perfect for 0.05 through 20 cm³/rev feed sizes and is excellently suited for use in high-pressure machines for PUR molded parts, foam slab stock, refrigeration unit insulations and sandwich panels, for example.

GA range for challenging conveying

Manufacturing companies are constantly facing the challenge of making their products and processes more efficient. Oerlikon Barmag has supplemented the tried-and-tested GM range with the GA series, developed especially for the challenging conveying of high-viscosity media. The GA series pumps are available for conveying volumes of between 1.25 – 30 cm³/rev (0.6-144 l/h). They have been designed for pressures of up to 200 bar, for viscosities of up to 1,500 Pas as well as for temperatures of up to max. 225°C. With this range of pumps, Oerlikon Barmag offers its customers tailor-made solutions for many technical processes in which high-precision and even metering is of paramount importance.

The drum pump – conveying and metering using a single unit

With the drum pump, the Oerlikon Barmag pump specialists have created a pump designed specifically for conveying and metering high-viscosity materials such as adhesives, silicones and other high-viscosity materials from drums and other large containers and for pressures of up to 250 bar. Its special features not only include the fact that it removes high-viscosity materials from the drum, but that it also meters the medium directly without any additional interim stops.

Gear pump and drum follower plate are aligned to each other so that the plate can effortlessly reach the bottom of the container, hence leaving a very low residue of < 1%. “This has a positive impact on both the material costs and the production process”, sums up Thorsten Wagener. The metering, which to date has been carried out in two steps requiring scoop-piston and metering pumps, can now be merged in into a single unit with the drum pump.

Pic: Precision gear metering pump