#Spinning

Oerlikon Experts share their know-how online

An overview of the Oerlikon Manmade Fibers webinars in the fourth quarter of 2020:

Factory know-how from a single source – A boost for your efficiency

4. November 2020: 11:00-11:45h CET

Speaker: Jochen Adler, Oerlikon Manmade Fibers CTO

From melt to yarn, fibers and nonwovens. At Oerlikon Manmade Fibers you get the entire factory know-how from a single source. From the planning and construction of highly complex production plants and competent customer services, Oerlikon Manmade Fibers offers everything for a successful business. Oerlikon is the right partner, especially – but not exclusively – for newcomers in the textile industry.

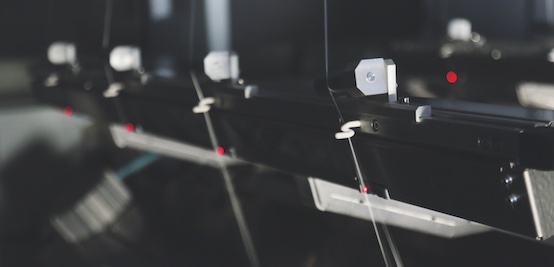

VarioFil – Your compact spinning solution

11. November 2020: 11:00-11:45h CET

Speaker: Ralf Morgenroth, Head of Engineering Textile Machinery BB Engineering (BBE)

Green Technologies – Join us on the road to a sustainable fiber industry

2. December 2020: 11:00-11:45h CET

Speaker: Markus Reichwein, Head of Product Management Oerlikon Manmade Fibers

The right technologies for recycling are a key requirement for a sustainable manmade fiber industry. Oerlikon Manmade Fibers describe a cascaded approach into new technologies as well as different material sources outlining your need for versatile solutions.

VacuFil – Your future upcycling plant, from waste to value

9. December 2020: 11:00-11:45h CET

Speaker: Matthias Schmitz, Head of Engineering Recycling Technology, BB Engineering (BBE)

The speaker of Oerlikons Joint Venture partner BBE presents the innovative PET recycling system VacuFil. It combines gentle largescale filtration and controlled intrinsic-viscosity build-up for consistently outstanding melt quality. The vacuum-unit - located next to the filter – quickly and reliably removes volatile contamination. The modular structure of the VacuFil range offers numerous possibilities for the process guiding system. Whether as a standalone solution with downstream granulation or as an inline version including 3DD additive feed – customer requirements can be optimally catered for with customized system configurations.