#Spinning

Hybrid customer service is currently the present and future

Oerlikon’s global Service Network combined with digital solutions:

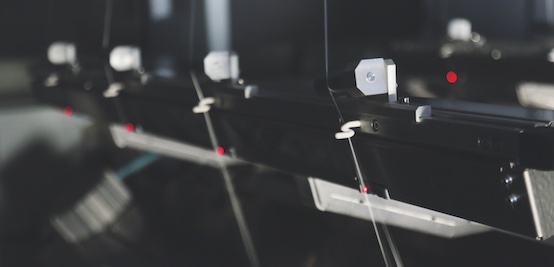

The range of customer services for the machines and systems of the Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven competence brands is broad and covers all customer requirements throughout the world. The ‘Start-up Services’, such as assembly and commissioning for the products that are continuing to be delivered during the coronavirus pandemic, are presently the greatest challenge. However, Oerlikon has excellent local service set-ups in its core markets of China, India, the USA and Turkey. Customers in Europe are looked after by staff at the German sites. As a result, virtually all projects have been successfully carried out over the past few months despite the difficulties. This was the case above all in China. Due to the travel restrictions relating to China, experienced construction site managers from Germany were involved by mean of videoconferencing, for example. “A particular challenge for all parties – but well-mastered by our team together with our customers in accordance with the circumstances”, explains Wolfgang Ernst, Head of Customer Services and Service Sales at Oerlikon Manmade Fibers.

Additional temporary staff on site

“Our local representatives provide support in those countries without own Oerlikon Service Station”, adds Ernst. Collaboration during these weeks and months has been even more important and has been going extremely well. And the locations in Germany have been providing Oerlikon Manmade Fibers online training seminars and intensive customer care using Microsoft Teams and Skype. “Currently, we are recruiting additional local temporary staff on site from our extended Service Network, training them – extensively online as well – and then bringing them together with local Oerlikon employees at the construction sites”, explains Wolfgang Ernst. To this end, ‘Start-up Services’ would continue to be complemented by ‘Service Lifecycle Management’ services such as upgrades, modernizations, maintenance, servicing and repairs.

‘You have to be able to roll up your sleeves and touch the machines’

To the extent it is possible, Oerlikon is currently providing ‘Technical Services’ and ‘Advanced Services’ – where it is actually necessary to be present at the system with experts – using videoconferencing. “Here, there are of course limitations. You have to see, listen to and feel a machine. You often have to roll up your sleeves and touch the machines to make improvements and increase efficiency”, states the German engineer. However, customers are currently only rarely requesting so-called ‘performance checks’. Local concerns have, understandably, shifted elsewhere. But Oerlikon can carry out analyses and optimizations of the processes, hardware and software to a certain extent by means of remote access. Even before the coronavirus pandemic, the majority of the Manmade Fibers segment’s customer services were being provided – in collaboration with customers – in a digital, hybrid form. “Because, generally, we additionally deploy experienced engineers and technologists from the international Oerlikon network on site in order to provide the necessary services for all customers directly”, continues Ernst.

Supply chain up and running

There currently continues to be a reliable supply of Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven original parts. “At the start of the coronavirus pandemic, the supply chain was stable – and it continues to be so. The logistics with all our partners across the globe are running smoothly”, comments the experienced Service Manager. Of course, Oerlikon’s customers can also place orders online using the ‘myoerlikon.com’ e-commerce shop. Items are then swiftly dispatched depending on the availability at our worldwide warehouses.