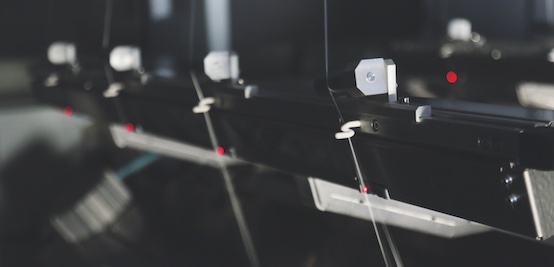

#Spinning

Exciting mix of current topics focusing on digitalization, the circular economy and personal protective equipment (PPE)

The focus of the ‘Dornbirn-GFC 2020 – Webinar Week’ will be on speeches and discussions on the following topics: ‘Smart, Integrated, Digital Textile Production Chain’, ‘Personal Protective Equipment (PPE) – a Challenge for the Industry in Europe?’, ‘New Recycling Technologies – what are the Challenges?’, ‘Circular Economy in the European Industry Recovery’ and ‘Future Rules & Regulations for Textiles – what should be expected from the EU?’.

The opening speech comes in the form of a keynote on the topic of ‘The Green Deal and its Implications for the Textile Industry’ by Leonore Gewessler. She has been the Federal Minister for Climate Protection, Environment, Energy, Mobility, Innovation and Technology for the Republic of Austria since January 2020. Furthermore, she was the Managing Directive of the Global 2020 environmental organization between 2014 and 2019.

Digitalization and sustainability

Tracking and tracing products in complex production processes using state-of-the-art digitalization technologies is at the core of the speech to be given by Sylvain Huck, Technology Manager Digital at Oerlikon Manmade Fibers. He will be talking on the topic of ‘Yarn DNA supported by Digitalization’ (all speeches will be held in English) on September 16, 2020, between 1 and 1:20 p.m. The following day, Markus Reichwein, Head of Product Management at Oerlikon Manmade Fibers, will be addressing another important current topic: ‘On the Road to a Sustainable Manmade Fiber Industry’ is the title of his presentation, which he will be giving on September 17, 2020 between 2 and 2:20 p.m. In his speech, he will be presenting the mechanical and chemical recycling solutions that the manmade fiber industry is currently pursuing.

Protective masks

The hot topic of discussion currently is protective masks and apparel. As a result, the demand for filter media – and those made from meltblown nonwovens in particular – has been extremely high since the start of the coronavirus pandemic. The Oerlikon Nonwoven meltblown technology is recognized by the market as being the technically most efficient method for producing highly-separating filter media made from plastic fibers. The capacities for respiratory masks available in Europe to date are predominantly manufactured on Oerlikon Nonwoven systems. In his ‘Leading Meltblown Technology for the Production of Face Mask Filter Media’ presentation, Dr. Ingo Mählmann – Head of Sales & Marketing at Oerlikon Nonwoven – will take the participants on a journey between 9:40 and 10 a.m. on September 17, 2020, introducing them to the secrets of meltblown technology. Because manufacturing protective masks, which help us control the dangerous coronavirus, requires ramping up the filter performance considerably. For this, spunbond and meltblown materials have to be electrostatically-charged. Here, the Oerlikon Nonwoven ecuTEC+ electro-charging unit is the key to success.

Tradition maintained

One tradition of the Global Fiber Congress has to be maintained even in the age of the coronavirus pandemic: to this end, the ‘Paul Schlack/Wilhelm Albrecht Prize’ awards ceremony will still take place within the context of the digital ‘Webinar Week’. You can find all further information and the options for registering on the following Website: www.dornbirn-gfc.com