#Spinning

Cationic-dyeable yarns have established themselves in the market

Energy-efficient yarn manufacture

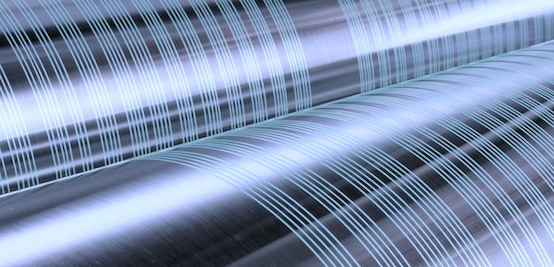

An additive in the melt ensures easier and superior uptake of dye, meaning that this special type of yarn uses very little water during the dyeing process and hence generates less environmental pollution. As a result of (chemically-) modifying the polymer, the fibers or filaments score points due to the lower temperatures required within the dyeing process, while producing consistently-brilliant dyeing results. The product is visually striking with its extremely-shiny, lively colors. Excellent processing properties – with simultaneously extremely low energy consumption and considerably reduced CO2 emissions – ensure a high level of efficiency in the case of this sustainable product.

The high capacity and the favorable production costs associated with the direct spinning process make the yarn considerably more attractive for further processing compared to production methods available to date. This opens up a new, broader application window for cationic dyeable yarns.

International yarn manufacturers have been producing such yarns within the context of the POY and FDY process on machines and systems supplied by the Remscheid-based solutions provider for 30 years now.