#Spinning

Oerlikon Manmade Fibers Segment focuses on filament, staple fiber and nonwovens

Oerlikon sells tape and monofilament technologies to Starlinger

The Austrian Starlinger Group based in Vienna will take over the German business unit from Chemnitz – also known under the brand name ‘Barmag Spinnzwirn’. The purchase contract was signed accordingly by both companies this week. The final closing is planned for the end of the third quarter of this year. Both parties have agreed to not disclose the purchase price.

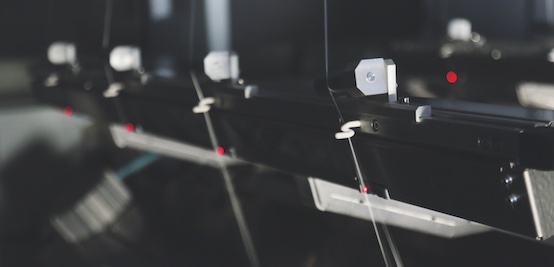

Over the last decades, ‘Barmag Spinnzwirn‘ has been successfully established in the market as a technology-trendsetter. The Oerlikon Manmade Fibers Segment unit provides their extrusion plants for the production of tape and monofilaments for polypropylene (PP), polyethylene (PE), polyamides (PA) und polyester (PET) as turnkey plant-design solutions. Another market success for the Chemnitz branch of the German parent company Oerlikon Textile GmbH & Co. KG, Remscheid, were the recently launched automatic winders, WinTape and WinTape XXL as well as the EvoTape process for film extrusion lines.

The technologies for selected high speed winders and precision winders for special applications like aramid or carbon will be sold to Starlinger as well. The business unit has a very solid international customer base with long-standing successful relationships. In 2015, a new, innovative technology centre for R&D and the performance of customer experiments was put into operation. The Chemnitz site currently employs about 160 members of staff.

“We are divesting our tape and monofilament technologies as well as our site in Chemnitz as we are convinced that ‘Barmag Spinnzwirn’ will be develop even better through a broader market access and through more synergies under the new owner as this is medium- and long-term possible within our segment environment. We will focus within our core business of filament, staple fiber and nonwovens plants with automated Industry 4.0 solutions in order to continue to actively shape the future of our company and the manmade fibers industry,” explains Georg Stausberg, CEO of the Manmade Fibers Segment.

“In the Austrian company Starlinger, we have found a buyer for our business unit in Chemnitz, who – as a worldwide leading supplier of plants for the production of woven plastic sacks, plastic recycling and refinement – has excellent access to the market and can thus continue to successfully develop the ‘Barmag Spinnzwirn‘ business. We have decided, to also hand over the brand name to guarantee a smooth transition,” Stausberg elaborates.

Angelika Huemer, Managing Partner of Starlinger & Co. GmbH, explains: "We are pleased to be able to make a promising and attractive addition to our product portfolio with 'Barmag Spinnzwirn', a very interesting and attractive option for the customers of the Starlinger Group. The resulting synergies in technical as well as commercial terms will underpin our leading position in the world of textile packaging and its applications and lead to new, innovative and customer oriented solutions in the medium-term. We intend to strengthen the production site Chemnitz further, the employees of the 'Barmag Spinnzwirn' we warmly welcome in our ‘Starlinger family’”.