#Software

3D adoption a decade later: There’s room for improvement

Recently, the key areas of focus for technology adoption have been in the areas of PLM, 3D technology and e-commerce. Over the last several years, many companies have realized the importance of technology in order to collaborate remotely, make faster decisions and shorten time to consumers, but Covid-19 has greatly accelerated the need for adoption.

But, are companies actually implementing these technologies so that they’re effective?

Is 3D technology really a game changer?

After 10+ years of 3D, can companies point to a workflow that has been a “game changer?” Has 3D adoption delivered a measurable ROI? Is 3D technology being used properly throughout the supply chain?

When you ask fashion brands and retailers why they adopted 3D, the overwhelming reply usually includes one or more of these responses:

• To save sample time and cost

• Faster decision making and time to market

• Better collaboration internally and with suppliers

• Sustainability

These are all valid reasons of course, but has 3D been the “game changer” expected in a company’s design and development process?

For companies dedicated to successful 3D implementation, this technology has completely transformed their process. In these successful implementations, we see most, if not all, early sampling done virtually, and there is better collaboration between design, merchandising and production teams, plus 3D assets are now leveraged for web content, virtual catalogs and even to replace photo shoots.

However, there are several areas where fashion companies could improve their use of 3D.

3D for fit

Ten years ago, the argument for 3D implementation was focused on 3D for fit. Patternmakers and technical designers discussed using morphable avatars to help validate a pattern and fit. In the 3D for fit scenario, 3D technology is simply a new tool patternmakers and technical designers did not have before. After all, wouldn’t a company want to feel confident that what they reviewed as a 3D sample is accurate and actually manufacturable?

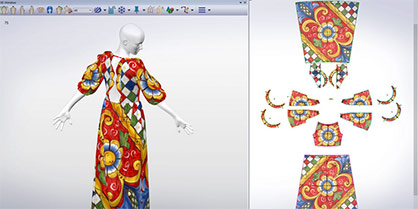

As the 3D visuals became better and more realistic, the shift focused from the fit to design. In the design workflow, we’re less concerned with pattern accuracy or manufacturability and more focused on photorealistic samples that will help make faster style revisions and allow for these 3D assets to be leveraged by merchandising and sales teams.

Both of these uses for 3D are important to create a more modern and efficient workflow. Many brands might even benefit from adopting two 3D solutions in a workflow; one specific to design and one that is more pattern-reliant and focused on fit, pattern consistency and manufacturing.

The latter use of 3D is largely being ignored as the industry chases solutions that can produce pretty pictures. When you ask yourself the question, “What builds a brand with staying power?” the answer is fit, quality and design, which begins with great patterns.

3D adoption by suppliers

Brands and retailers drive the majority of 3D use at the supplier level. Factories are now asked to adopt the same 3D solution that the brand is using in order to submit proto samples digitally, rather than submit physical samples. In this scenario, sample times and costs go down, and companies can point to a more sustainable workflow with less waste. Is that all we should be looking at from our suppliers?

While pushing factories to adopt 3D is beneficial, it’s short sighted if only used because a brand or retailer mandates it. As an industry, we should be educating our suppliers on why they should be using 3D to help in their day-to-day workflow for all of their clients. Factories should begin using 3D for all projects, not just clients who are already using it.

At the factory level, 3D should be used for both virtual sampling and internal matters. Nowadays, factories make the patterns so they should use 3D to check patterns and fit, scale artwork and other production related tasks. In order to modernize their workflows, factories should look to incorporate 3D regardless of whether or not they’re asked to by brands.

3D for an improved supply chain

Many companies will also see measurable ROI from the adoption of a 3D solution due to the reduced number of physical samples, fewer commitments to fabric and lower shipping costs. For companies that are “mature 3D users,” leveraging 3D content for websites and photo shoots will also bring immediate and quantifiable ROI. Photo shoots are extremely expensive, and in most cases, all the physical samples needed for the shoot are not ready. By using 3D samples, you solve both problems and at a fraction of the cost.

There are also areas where an ROI exists from 3D adoption, but is more difficult to measure. By using 3D, companies collaborate better, which leads to faster decision making and time to market. Companies are still evaluating how to put a dollar figure on being more efficient. Is it as simple as a lower head count because technology helps you do more with less? Does better decision making in apparel development lead to better sell throughs and fewer markdowns? 3D adoption enables agility, driving a more efficient and profitable supply chain.

The next evolution of 3D

What should we expect next in this 3D evolution? Today, companies that provide 3D solutions have established their identities in the marketplace. Some 3D solutions are very much design driven and others are very focused on fit, patterns and manufacturing. Perhaps we will start to see new solutions that offer new workflows we have not seen, or that have been on everyone’s wish list. We may see solutions that go from 3D to 2D or solutions that will provide tools for calculating fabric yields and costs within the 3D application.

3D will continue its evolution in the fashion industry, so it’s important to stay educated on new technologies being developed, be open to newness and change and view the adoption of 3D technology as an integral part of an agile workflow. 3D adoption is not a silver bullet that will solve every problem for an apparel company. It is, however, a very important part of a connected supply chain.