#Software

Avatars -the new top models!

The fit quality is proven by testing on humans. How can avatars contribute in the current pandemic situation to keep product development running? In the apparel industry, too, many people are currently working from home or are very much on their own in the office. Product developers are sent products, but cannot technically validate the fit because there is no possibility of using a fitting model. With ouravatars, which are all based on real body dimension data from representative measurement surveys, we can provide digital models to keep the processes running.

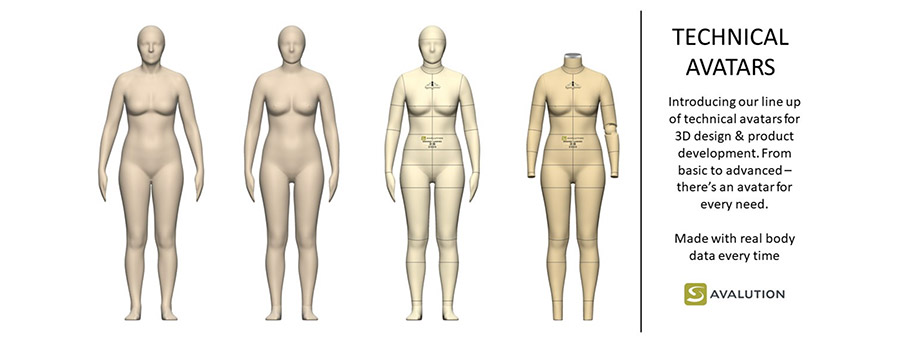

Which avatars are available? We have developed different technical avatars for different work steps. Depending on the task a product developer faces, we can provide him with the appropriate avatar –regardless of which 3D system is used. The 3D systems usually offer avatars, but these are not realistic enough to make final decisions about the fit that should represent the typical target customer and conform the quality requirements of a brand. We offer single avatars, but also complete rows of a standard size chart or even a brand specific size chart. Here the avatars have a big advantage over a fitting on a fit model: they are available in every size, so that the complete grading can be checked in all sizes.

What makes the avatars from Avalution stand out? Our avatars are all based on real body dimension data from representative measurement surveysthat we have been taking for many years, and therefore correspond to real bodies. This allows them to very realistically depict the typical body shapes of target customers, even in larger sizes or special figure types. It is also possible to map special morphotypes, i.e. specific body shapes and proportions. The avatars are prepared in such a way that they can provide the same fit results in the virtual fitting as in the real model fitting.

They also have dimension lines that visualize the position of the body measurements on the avatar, which probably offers the biggest difference to many other avatars available. These can provide the product developer and the supplier with valuable information on where exactly they need to start with all fit areas in the case of fit problems or adjustments. This means that the fit can be objectively evaluated and further developed with them.

How can I start with an avatar – is training necessary? The avatars can be provided in a standard format (OBJ) that can be read by all common 3D systems. This means that no special training is necessary before use.