#Textile processing

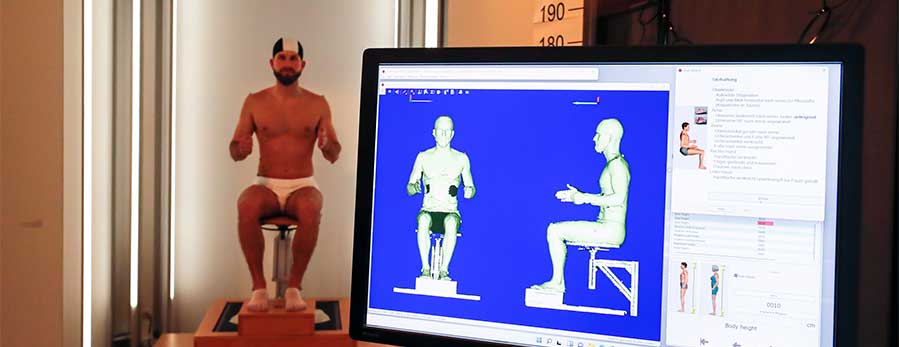

Avalution measures German soldiers in 3D

The next few years will see around 2,500 soldiers of the Navy, Air Force, Army, Joint Support, Enabling Service and Medical Service measured at six locations throughout Germany. This project will establish a valid, comprehensive and up-to-date database of body measurements and shapes that will enable the development of target group-specific clothing and personal equipment that fits even better and the procurement of the items in the required quantities. The data collected from the customer-specific 3D anthropometric survey project is also used to create digital test persons (avatars). These can be incorporated into ergonomic analyses of vehicle interiors to adapt the vehicles as accurately as possible to the specific requirements of the armed forces. All personnel, whether short, tall, broad or slim, must be able to optimally work or be transported with their equipment in these vehicles.

The need for up-to-date data stems from people changing over the decades, with an average statistic growth of one centimeter per decade. For example, there is no up-to-date data on the body measurements and body shapes of Bundeswehr soldiers – data that could create accurate size tables for clothing and personal equipment. The current 3D anthropometric survey project is aimed at changing this situation. “For special target groups such as the Bundeswehr, up-to-date data is necessary because it can be used to address soldiers’ clothing and equipment requirements in the best possible way during product development, ensuring that the correct sizes are available for the soldiers. If their clothing and equipment does not fit properly, this can become a safety risk in an emergency,” says Michael Stöhr, Managing Director of Avalution.

“The 3D anthropometric survey is an essential element in the varied activities within the Bundeswehr scope of clothing management digitalization. “We can only provide the soldiers with the precisely-fitting clothing and personal equipment they need, punctually and in the correct quantities, if we have up-to-date and accurate data on body measurements and body shapes”, says Dr. Carsten Zimmermann, a scientist at the Bundeswehr Research Institute for Materials, Fuels and Lubricants (WIWeB) and project manager for the 3D anthropometric survey.

Soldiers from all branches of the armed forces (i.e., Navy, Air Force, Army) will be measured with a 3D body scanner at six locations over two years. This will ensure that the data is as representative as possible for all members of the Bundeswehr. More than 340 soldiers of the German Navy have already been measured at the Naval Technical School in Parow near Stralsund, the first site of the measurement campaign. The next site will be the Jürgen Schumann Kaserne, the Noncommissioned Officer Academy of the German Air Force, in Appen near Hamburg, where the project will continue from the end of April 2022. The fall of 2022 will see more surveys at the German Army HQ in Munster, and additional survey locations in 2023 will be Cologne/Bonn, Koblenz and Berlin.

The soldiers will be recorded and digitalized in four postures by a non-contact, 3D body scanner at each survey site. A digital questionnaire will also record socio-demographic data, including family background, position within the armed forces, sporting activities and clothing preferences. The entire process takes less than half an hour for each participant.

The 3D anthropometric survey of the Bundeswehr will continue until the end of 2023, after which the results will be evaluated, processed in a database and finally handed over to the Bundeswehr for further use in 2024.