#Research & Development

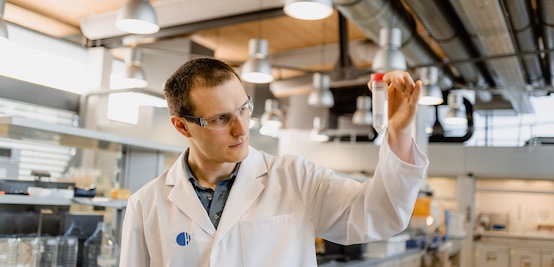

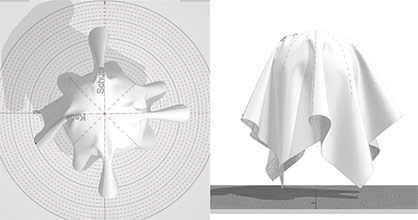

Digital material parameters for a realistic 3D simulation

In laboratory procedures specially adapted for 3D simulation, the Hohenstein experts use fabric samples to determine the material's physical characteristics such as weight, thickness, stiffness and stretch. This is followed by testing of the fold volume and shape using a drapemeter. The results are converted into the various file formats of the 3D simulation systems so that the digital material parameters are available in the appropriate file format for each customer. Upon request, Hohenstein also simulates the associated draping images in 3D to visualize the specific draping behavior of the tested material for the customer. That way, digital prototypes can be created that subsequently accelerate the approval processes and require significantly less material when making real prototypes for production.

As an accredited laboratory for the comprehensive quality testing of textiles, Hohenstein combines many years of expertise in traditional garment fit development with digital technologies. In addition, the Hohenstein Academy offers numerous workshops about pattern development and 3D fitting.

More information:

https://digital-fitting-lab.hohenstein.com

https://www.hohenstein-academy.com/en/

Contact address for clothing companies:

digitalfittinglab@hohenstein.com.