#Research & Development

New DIN SPEC supports the development of textiles with low microfibre discharge

Test method is suitable for materials made of man-made and natural fibres

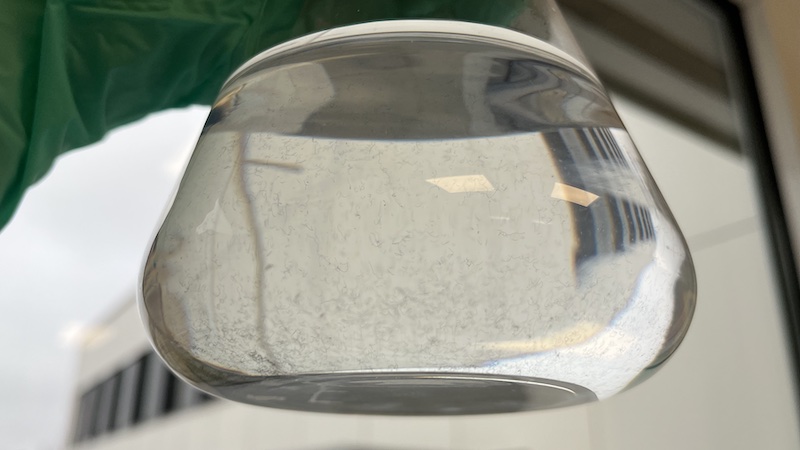

During the manufacture and use, but also during the care of textile products made from synthetic materials, fibres are released into the environment and pollute the oceans as microplastics, for example. Depending on the washing programme selected, i.e. the temperature and mechanical load, different quantities of textile fibres end up in the wastewater, even when washing items made from natural fibres. This is where the DIN SPEC 19292 test procedure comes in: After a simulated washing process of a fabric sample using tabletop equipment and a defined amount of water, the sample water is filtered and, based on a visual evaluation with a microscope, the degree of fibre fragmentation by the textile material is determined.

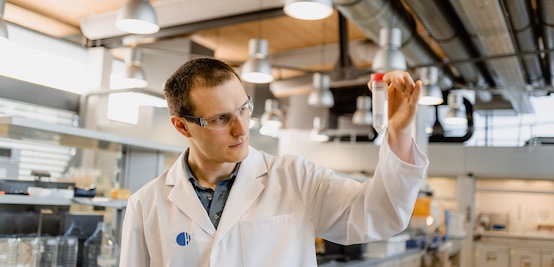

“With our broad expertise in sustainable solutions, we have been supporting companies in the textile industry for years in better understanding the fibre discharge of their products into the environment, making it objectively measurable and reducing it in a targeted manner,” says CEO Dr Timo Hammer, summarising Hohenstein's contribution to the new DIN SPEC.

On the industry side, Under Armour was looking to develop an easy-to-use, accessible solution for its producers that would allow the company and others to avoid microplastics through product development. “In the apparel industry, assessing the fibre abrasion of garments can be a costly and time-consuming process,” explains Kyle Blakley, Senior Vice President of Innovation, Development and Testing at Under Armour. “With Hohenstein's expertise, our team was able to align our innovative new test method to the globally recognised framework of DIN SPEC 19292. This exciting milestone supports our aim to make the test method as accurate and internationally accessible as possible.”

In addition to working on the new DIN SPEC 19292, Hohenstein also offers further tests to determine the extent to which (micro)fibres degrade in the wastewater of production plants or in household laundry and how harmful the fibre residues are to the environment. The tests are carried out according to Hohenstein’s in-house methods as well as international standards and procedures.