#Research & Development

Elektrolysis made in Baden-Württemberg

DITF develop technology for new, reinforced membranes for electrolyzers

Hydrogen is a clean energy carrier. When converted to electricity in a fuel cell, it is characterized by a very high energy yield. Hydrogen is also transportable and can therefore be used locally by consumers. Hydrogen technology is particularly important for energy-intensive industries such as steel production or in the operation of refineries. But hydrogen is also very popular for modern mobility solutions: as a transportable energy carrier that is also locally emission-free.

Construction of a modern electrolyzer

In the joint research project 'Electrolysis made in Baden-Württemberg', the DITF are participating in the construction of a state-of-the-art electrolyzer for alkaline water electrolysis, which will serve to transfer technology to industry. The project is coordinated by the Center for Solar Energy and Hydrogen Research (ZSW), which will build the demonstrator with an electrical output of one megawatt. The task of the DITF is to develop and manufacture nonwoven-reinforced membranes for the electrolysis cell.

Water electrolysis is an electrochemical process with the aim of obtaining hydrogen from water. In an electrolysis cell, water is split electrochemically and releases gaseous hydrogen at a cathode and oxygen at an anode. The anode and cathode are separated by a membrane. The passage of current is not interrupted by the membrane. Depending on the design of the electrolytic cell, the ionic conductivity of the membrane allows the exchange of ions. The membrane is gas-tight and thus prevents the mixing of the gases produced at the anode and cathode.

Membranes of this type are already in widespread use, but they usually have a relatively high ohmic resistance due to their material thickness. A correspondingly higher energy input is required for electrolysis. Thin and highly efficient membranes with better electrochemical properties, on the other hand, have so far not been robust enough, especially when used in larger cells. They are sensitive to mechanical stresses and are prone to stress cracking.

Reinforced membranes from the DITF

As part of the research project, membranes made of polymers are being produced at the DITF that are modified and thus precisely tailored to their task. The membranes exhibit excellent electrochemical properties. They are chemically stable in an alkaline environment, i.e. under the conditions that prevail inside the electrolytic cell. The membranes should also have good long-term stability. This means that they work almost faultlessly even under continuous stress. The membranes are inexpensive to manufacture and use.

The mechanical stability of the membrane is a central point in the development. On the one hand, it should be as thin as possible in order to work highly efficiently. On the other hand, it should not fall below a certain thickness to ensure mechanical load capacity. The mechanical load cannot be avoided, since during block assembly the membranes are pressed together with the mostly porous, structured surfaces of the electrodes in the block.

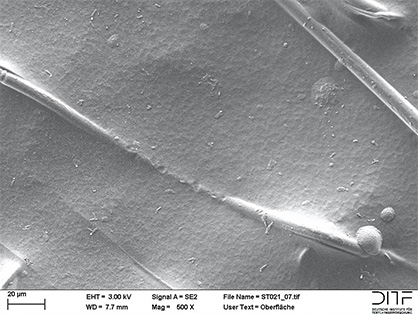

To alleviate this difficult situation, researchers at the DITF are taking a special approach: The membranes can be mechanically reinforced by using nonwovens made of ultrafine fibers (fiber diameter 0.2-2µm). The development of suitable nonwovens, their structural design and the choice of their chemical composition are just as great a challenge as the manufacture of the membranes. A specially developed integrated reinforcement frame made of composite materials also absorbs mechanical pressure loads and provides additional protection for the membrane. In addition to pure mechanical stabilization, it will be possible to use the nonwovens to reduce the passage of hydrogen through the membrane. The interface between the membrane and the nonwoven has a special significance in the structure of this composite: The electrical contact resistance must be kept low here so as not to impair the efficiency of the cell. This can be influenced by the choice of material for nonwoven fabrication or by surface treatment of the nonwoven. In this way, the electronic properties, but also the fiber-matrix (or fiber-membrane) adhesion, which is crucial for achieving an increase in stability through the use of nonwovens, are ensured and further developed.

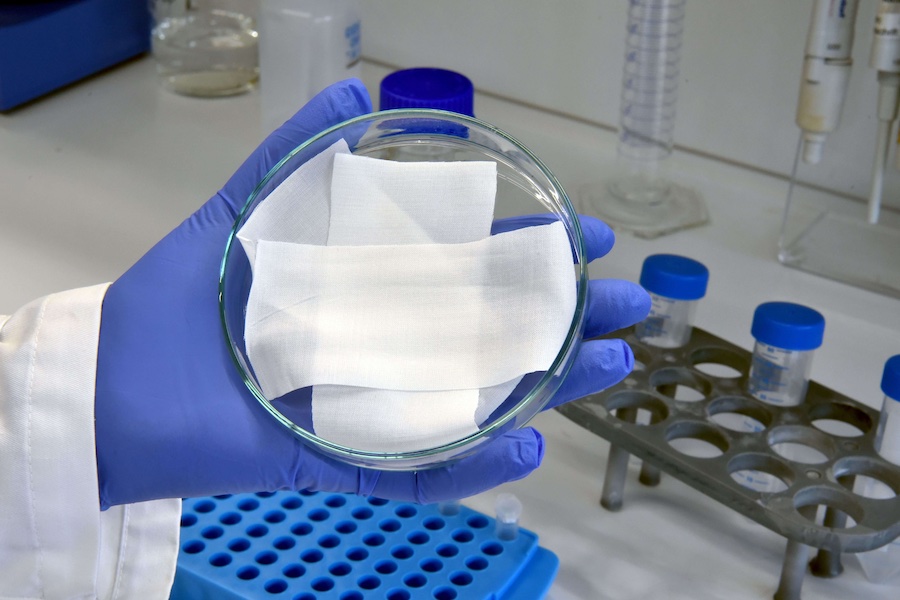

Bringing together such disparate materials as an electrochemical membrane and a textile nonwoven is a very challenging undertaking. This makes the first promising laboratory results all the more noteworthy. The first nonwoven-reinforced membranes are available and are being tested for their practical suitability. The next step will be to optimize the structure of the membranes. At a later date, they will then be in service - for the time being within the demonstrator, which will set the state of the art in this joint project.

Project information

Under the slogans 'Electrolysis made in Baden-Württemberg', the Baden-Württemberg Ministry of Economics, Labor and Housing is funding a collaborative research project with five million euros. The lead partner is the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW). In addition to the German Institutes of Textile- and Fiber Research Denkendorf (DITF), the collaborative partners are the German Aerospace Center (DLR) and Hahn-Schickard Gesellschaft für angewandte Forschung (HS) in Stuttgart. The aim is to develop a modern, highly efficient water electrolysis plant that will serve as a demonstrator for technology transfer. The technology is intended to help plant engineers and component manufacturers position themselves advantageously in international competition. Specialist companies will be involved in the development project from the outset. The project sees itself as an initiator for state-of-the-art electrolysis production in Baden-Württemberg.