#Recycling / Circular Economy

EU Research Project

European research project addresses textile waste through integrated recycling technologies

Europe's textile and clothing industry employs 1.3 million people and generates around 170 billion EUR annually. However, it produces 10.9 million tonnes of post-consumer textile waste each year, with less than 1% currently recycled through closed-loop processes back into new textiles.

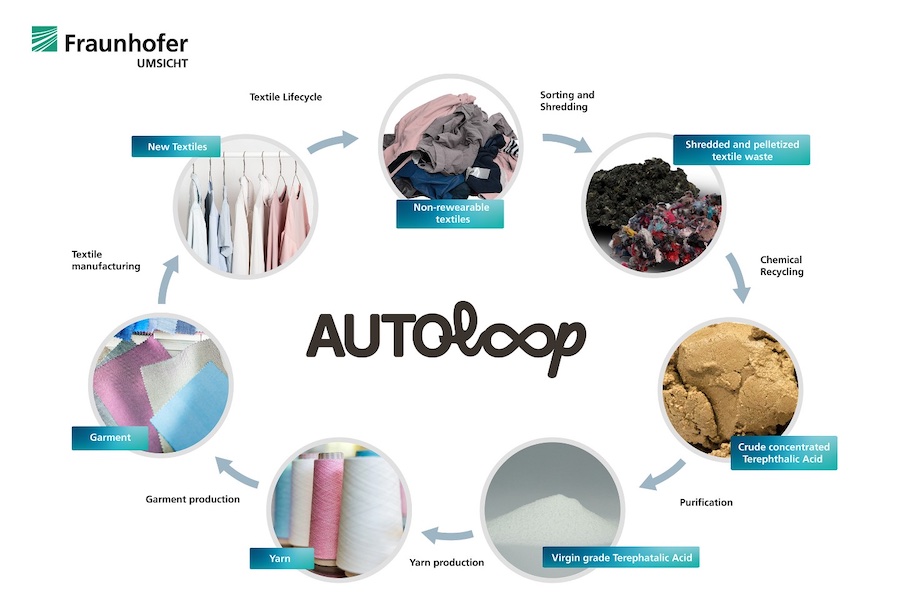

»The textile industry is at a critical juncture,« explains Dr. Thomas Fehn, Coordinator of AUTOLOOP from Fraunhofer UMSICHT. »This project represents a paradigm shift from waste to resource, transforming discarded clothing into valuable raw materials for new garments.«

Technological approaches and work packages

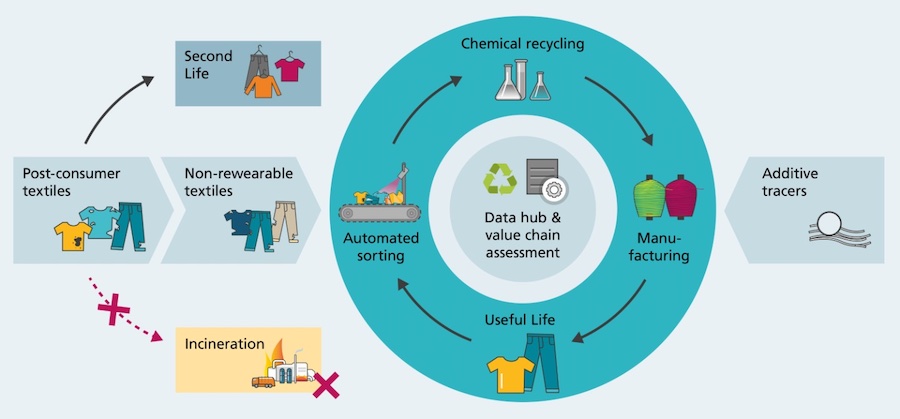

AUTOLOOP comprises several key technological innovations for the complete recycling of polyester-based (PET-based) textiles, which are being further developed and validated by the project partners:

- AI-Powered Sorting: ZORITEX's artificial intelligence system identifies over 15 different fibre types and their blends using hyperspectral near-infrared technology. This automated approach could increase sorting throughput tenfold whilst reducing costs by 50-75%

- Chemical-Free Recycling: AALTO's Ioncell® process uses innovative ionic liquid solvents to extract cellulose fibres from textile blends, achieving over 95% recycling rates without harmful chemicals.

- Advanced Synthetic Recovery: The ReSyn technology developed by Fraunhofer UMSICHT and SKZ breaks down synthetic fibres into high-purity building blocks for creating new materials, working efficiently even with contaminated textiles.

- Smart Fibre Tracking: TLX's IntegriTEX® technology embeds invisible identifiers in fibres, enabling contactless detection and complete supply chain transparency.

- Digital Integration: TEXROAD's cloud-based Data Hub standardises information management across the entire recycling process, ensuring compliance with emerging regulations like the Digital Product Passport.

Projected outcomes by 2050

If successfully scaled, AUTOLOOP's integrated approach could:

- Recycle 1.24 million tonnes of textile waste annually

- Achieve 96% material recovery rates

- Create over 130,000 new green jobs across the EU

- Reduce municipal waste management costs (currently 60-110 EUR per tonne)

- Significantly decrease the textile industry's reliance on virgin materials

A truly European effort

The project brings together 14 partners from seven countries, combining research institutions with industrial partners. Key organisations include ZORITEX (UK), AALTO University (Finland), Fraunhofer UMSICHT (Germany), TLX (Germany), and TEXROAD (Netherlands), along with additional partners across Europe. Additional partners include, ELT (UK), TRASBORG (Denmark), VTT (Finland), SKZ (Germany), S4L (UK), LEEDS (UK), NORION (Denmark), TEMASOL (Switzerland), and LGI (France).

Looking ahead

As European regulations on waste management continue to develop and demand for sustainable textiles grows, AUTOLOOP provides a research foundation for advancing circular economy principles within the textile industry. The project demonstrates how advanced recycling technologies can be integrated to create efficient systems for processing textile waste, supporting the transition from linear to circular production models. AUTOLOOP has received funding from the European Union's Horizon2020 research & innovation programme under grant agreement No 101181624.