#Spinning

Innovative Textile Recycling: New Partnership to simplify textile processing at the Recycling Atelier

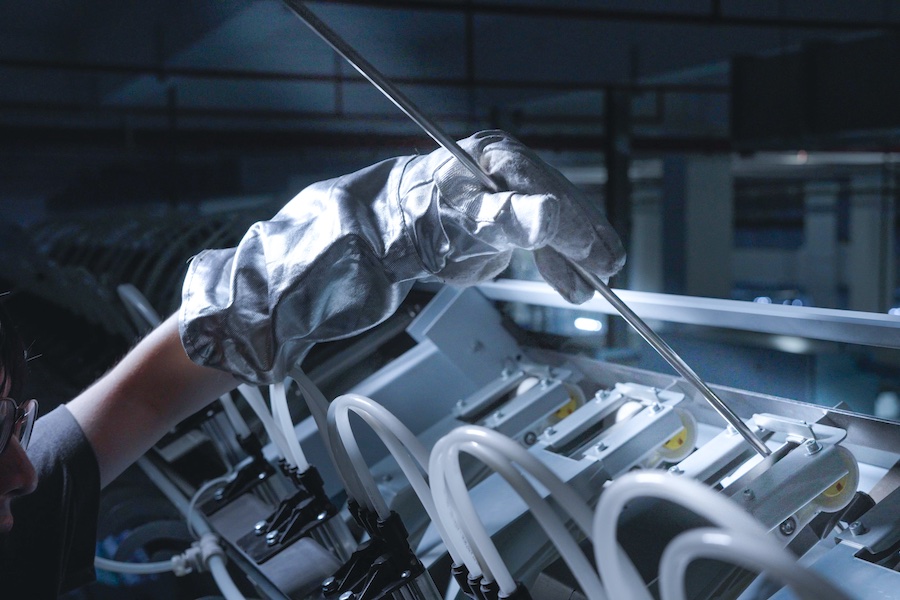

Savio Macchine Tessili S.p.A. specialized in the textile machinery sector for the yarn finishing segment. The Italian company offers a portfolio of winding, twisting, air-jet spinning, shrinking and bulking machines with manufacturing plants in Italy and Asia. It has been operating for more than 110 years. The partnership adds another step to the process chain for mechanical textile recycling, completing it and opening up research possibilities in the areas of winding and quality control of yarns.

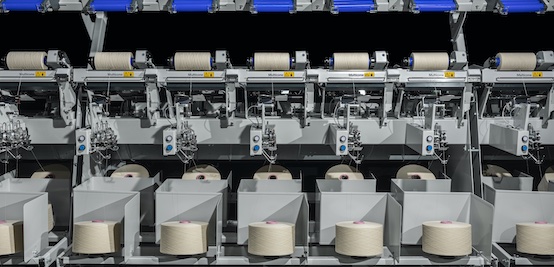

The Recycling Atelier partner network consists of twelve industrial companies that together cover the entire process chain of mechanical textile recycling. The addition of Savio Macchine Tessili S.p.A. is an important component for the high-quality recycling of textiles. Savio contributes not only by sharing their valuable know-how in the winding field. The company also provides Proxima Smartconer® winder to the Recycling Atelier. The winding process is crucial for the quality of the yarn. Winding is the last step of the spinning process where the yarn can be controlled and qualified before it goes to the downstream processes of weaving, knitting, dyeing, and finishing.

Know-how directly from the manufacturer

Dr.-Ing. Georg Stegschuster, Head of Recycling Atelier, says: “Savio winding machines offer high productivity, low energy consumption, premium yarn quality, automation, and data connectivity. Those criteria are ideal for the setup in the Recycling Atelier. Plus, we receive insightful know-how directly from the manufacturer. We are looking forward to the cooperation and the positive impact that Savio's involvement will bring to our applied research.”

Mauro Moro, CEO of Savio Macchine Tessili, is delighted about the partnership with the Recycling Atelier Augsburg: “The collaboration with the Recycling Atelier Augsburg is a step forward to advancing research in winding technology and quality control within the recycling context.”

Prof. Mesut Cetin, Institute Director of ITA Augsburg and professor at the Faculty of Mechanical and Process Engineering at Augsburg University of Applied Sciences, explains the impact and work of the Recycling Atelier: “The Recycling Atelier, ITA Augsburg and the Technical University of Applied Sciences Augsburg see themselves as a catalyst for industry towards sustainability. We welcome innovation and progress in any form. Whether application-oriented content or basic research, whether publicly funded projects or direct contract research - we are open to any exchange between industry and research.”