#Raw Materials

Plastic from cotton, outdoor from cotton, fluorescent cotton, cotton in 3-D design

Cotton – Useful Beyond Your Imagination: Cotton can make plastic, it can do outdoor, it can be fluorescent and in 3D-design.

A highly exciting session will deal with alternative uses of the renewable natural fibre in innovative products with a high utility value. The session will take place on Thursday, 18 March 2021 at 12:30 (GMT+1) in the Technical Track.

The use of cotton goes far beyond household textiles and clothing. In the session ‘Innovative Textile and Technical Products’, four examples make it clear that the use of the biodegradable raw material cotton has grown impressively. In fact, thanks to its intelligent properties, cotton can also be found in technical products or in smart textiles.

Michael Jänecke, Director of Brand Management Technical Textiles & Textile Processing at Messe Frankfurt, will lead the session with his extensive market experience. Among other things, he has been responsible for the organisation of the leading international trade fairs ‘Techtextil’ and ‘Texprocess’ for many years.

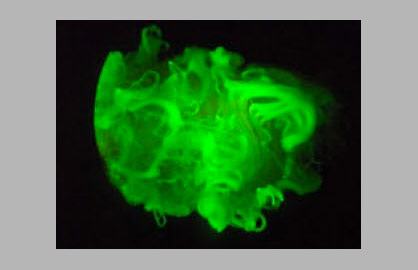

Case Study 1: Fluorescent, Super-magnetic and Water-repellent Cotton

Dr Filipe Natalio is a senior staff member and researcher at the Weizmann Institute for Science in Rehovot, Israel, working for the Plant and Environmental Research Department, affiliated with the Kimmel Centre for Archaeological Science. He presents the results of his work under the theme of ‘Raw Material Agriculture: Breeding Cotton with Unique Functions’, in which cotton can be equipped with fluorescent, super-magnetic and water-repellent properties. This is brought about biologically through the implementation of a specially developed glucose molecule in cotton. The development has the potential to be used in large formats in cotton-based functional materials and textiles.

Case Study 2: Cotton, not Plastic

Dr Noureddine Abidi is Professor and Director of the Fibres and Biopolymers Research Institute (FBRI) at Texas Tech University, USA. There he developed a process in which cotton is processed in such a way that it can be used as an alternative to plastic. This can also use short fibres or fibre residues that are not suitable for higher-quality processing. The resulting cellulose-based bioplastics are biodegradable. Bio-based plastics have a wide variety of commercial applications, including shopping bags, agricultural land coverings, bio-plastic packaging, and other single-use items. As a conceivable low-cost alternative to petroleum-based plastics, this innovation offers a way of reducing the amount of plastic in the environment.

Case Study 3: Innovative Padding and Fabrics for Furnishings and Outdoor

In a double lecture, Matthias Boehme and Daniel Odermatt present innovative textiles for the interior design and outdoor sectors. Matthias Boehme is the owner of the Textile Solutions & Consulting agency in Bremen. He presents product ideas for padding for use in furniture from the German nonwoven and composite manufacturer Norafin Industries in Mildenau. These are not made from oil-based synthetic fibres, but from cotton and other bio-based natural fibres and are used in home textiles (e.g., wallpaper) or for functional components for technical textiles and for clothing development.

Daniel Odermatt is Division Manager at fabric manufacturer Stotz & Co. AG, Zurich, Switzerland. The company is known for developing highly functional cotton fabrics. For example, extra-long staple fibres are softly spun and twisted and then woven in the highest possible density. The result is a dense all-weather fabric with natural properties and maximum comfort. The material is rainproof, completely windproof and equipped with a breathability that can only be achieved using natural materials.

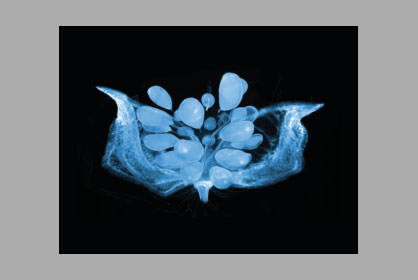

Case Study 4: 3D Cotton-Linen Fabric for the Treatment of Skin Diseases

Dr Iwona Frydrych from the University of Technology in ?ód?, Poland, is a professor at the Faculty of Material Development and Textile Design. Her topic is the support of the medical treatment of skin diseases using a 3D-design for clothing made of cotton-linen blends. Microcapsules with proven skin-soothing plant substances are applied to the material. The material treated in this way has direct contact with the skin. The content of the microcapsules is released by body heat and moisture. According to studies, this leads to relief from skin complaints.

We will continue to report on the other contents of the cotton conference in our press releases. The current conference news and programme details can also be found on the conference website. We look forward to active media coverage. Interview requests in advance are processed as quickly as possible. We are already inviting journalists to the conference and accreditations are possible at any time via the conference website https://cotton-conference-bremen.de/press/.

* When using the computed tomography image, please use the following copyright information: © FIBRE/ MAPEX/ University Bremen

canva-900-1-1-1.jpg)

canva-900-1.jpg)