#Other suppliers

Shelton Vision pushes the needle on AI-assisted quality control

Company’s most successful ITMA exhibition in over 50 years sees demand escalate for unique automated fabric inspection systems.

The company has subsequently been recruiting additional staff in order to beef up its operations to meet delivery times and to grow capacity for the ongoing increased demand.

“We are definitely seeing a ‘sea change’ across the textile industry, with a new generation of management rapidly embracing imaging technology and fully automated fabric inspection,” says Shelton Vision CEO and Managing Director Mark Shelton. “On top of all the throughput and first quality yield improvement benefits our automated fabric inspection can bring, companies throughout the industry, face difficulties in recruiting, training and retaining staff, especially those needed to carry out repetitive manual fabric inspection.”

At best, he adds, studies show that manual inspection can detect around 65% of faults present in the fabric, while the WebSpector offers automated defect detection of over 98%.

“Not only this, using machine learning, the vision system automatically trains new styles and our AI platform is continuously updating to achieve high accuracy of real time defect naming and grading to eliminate false positives and provide consistently accurate data for both roll cutting optimisation and yield increase, as well as for optimising fabric utilisation in panel cutting processes”.

Patterned fabric inspection

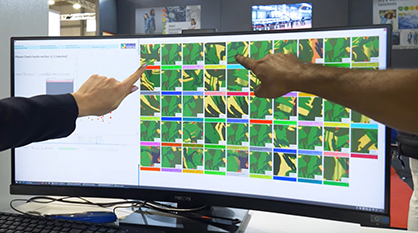

Building on its market leading vision system for plain, single colour textiles, Shelton’s patent-pending image processing techniques recognise and adapt to complex patterns – even those on fabric with significant distortion and deformation. Fabrics are not rigid and can be sheared or stretched while also being subject to local distortion, but the WebSpector system successfully deals with such anomalies in real time to provide a reliable inspection process at the same levels of plain fabric. The unique and advanced software techniques ensure a totally clean image, allowing the full detection of faults on fabrics running at high speeds.

Prior to ITMA 2023, the effectiveness of these techniques had already been validated through factory trials and the installation of the first systems sold.

To fully demonstrate and provide new customers with the opportunity to see the technology operating on their own fabrics, Shelton has invested in creating a purpose-built, full scale high speed in-house demonstration system at its headquarters in Leicester, UK. The increased level of interest is being further demonstrated by the constant stream of rolls now being received for new customer demonstrations .

While the automotive interiors and one-piece woven airbags sectors remain major destinations for this advanced technology, further finished fabric WebSpector systems are now currently being supplied to manufacturers of performance wear and high-end fashion, denim, outdoor upholstery, sunscreen, mattress ticking, window dressings and even carbon fibre composites. In addition to finished fabric inspection, there is also a growing demand for fabric forming/grey cloth inspection to streamline mending of both plain and patterned fabric.

Brand backing

“We are being greatly assisted by the increased quality expectations across value chains and the realisation by brands and larger corporations of what our technology can do – and on a more fundamental level, that a reliable fabric inspection system technology actually exists, after disappointments with previous technologies,” Shelton says. “These brands and corporations are actively promoting the adoption of our system to their fabric suppliers.”

Founded in 1940, the British Textile Machinery Association actively promotes British textile machinery manufacturers and their products to the world. The non-profit organisation acts as a bridge between its members and the increasingly diverse industries within the textile manufacturing sector.