#Nonwovens / Technical Textiles

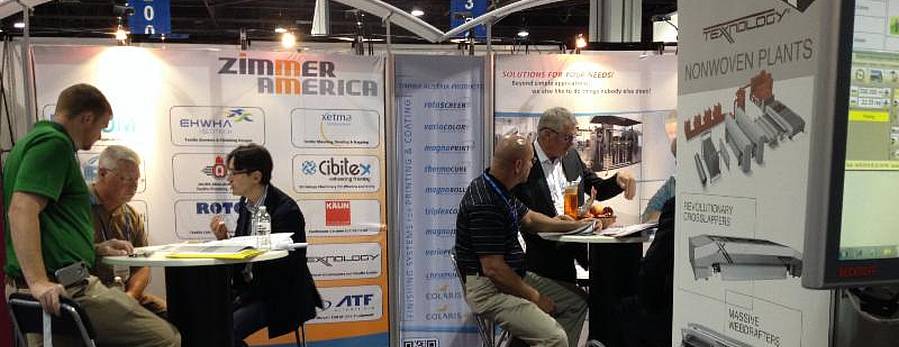

Zimmer at TTNA: Very productive 3 days with COLARIS-NF live demonstration!

LACOM from Germany was also represented at the Zimmer booth. LACOM is the world leader in laminating and coating machines. Duplex laminating and coating machines for simultaneous laminating of three webs are also available. LACOM offers machines that operate via gravure roller, multi-roller, hotmelt, slot die, scatter coat, and dispersion coat to fit the needs of multiple industries, from automotive lining to packing tape. Xetma Vollenweider (Germany) manufactures machines for Textile Finishing (also DRY mechanical finishing). Their product range includes machinery for: Napping, Shearing, Sanding, Polishing, Combined Napping and Sanding, Tigering, Brush-Sueding, Brushing, Combined Brush-Sueding and Sanding, Cleaning, Carpet Shearing.

Zimmer America along with TEXNOLOGY and BEMATIC discussed their new technologies with potential customers. These include:

- The new ELLITTICA elliptical needle loom from TEXNOLOGY, capable of operating vertically or elliptically, steplessly adjustable. It is the only needle loom in the world with this feature making it a revolution in elliptical needling.

- The direct needle line from BEMATIC and TEXNOLOGY, which consists of a BEMATIC Bemaformer web forming unit in combination a TEXNOLOGY ELLITTICA elliptical needle loom.

- TEXNOLOGY's state-of-the-art showroom at the facility in Fontaniva, Italy, where a direct needle line is installed and available for trials with customer material.

- TEXNOLOGY's new SINTESI Crosslapper X-Series, a revolution in efficient crosslapping.

Texnology's new technology is now available for trials at their showroom in Italy!

Pic: Roland Zimmer, CEO Zimmer America (left rear) and Bob Patterson, Sales Manager Zimmer America (right front) in customer meeting.