#Knitting & Hosiery

SHIMA SEIKI to exhibit at GMMSA Expo India

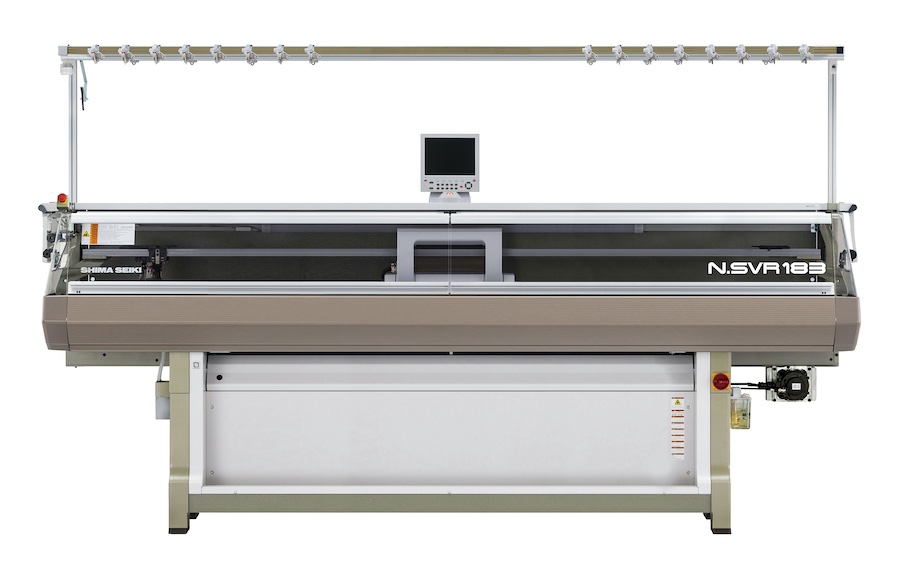

N.SVR®183

SHIMA SEIKI will be exhibiting its WHOLEGARMENT ® knitting technology whereby an item can be produced in one entire piece on the machine without linking or sewing. Its N.SVR®183 WHOLEGARMENT ® knitting machine produces WHOLEGARMENT ® knitwear using every other needle. N.SVR®183 is equipped with the R2CARRIAGE® system and a compact, lightweight carriage for high productivity. Shown in 14 gauge at the GMMSA Expo, N.SVR®183 is an ideal machine for flexible, entry-level WHOLEGARMENT ® production of 7-gauge items, with the versatility to respond to fluctuating market demand.

N.SSR®132

SHIMA SEIKI’s global standard in shaped knitting, the N.SSR® series, now includes an even more cost-effective choice. The new N.SSR®132 is shown for the first time in India, after being well-received by Indian delegates at the ITMA Asia + CITME 2025 exhibition in Singapore last October. It features high productivity with a compact, lightweight carriage and maximum knitting speed of 1.2 meters per second, as well as proven SHIMA SEIKI technology such as the R2CARRIAGE® system, the Digital Stitch Control System (DSCS®), spring-type moveable sinker system, stitch presser, yarn gripper and cutter, and takedown comb. New features include a 52-inch (132 cm) knitting width for supporting larger sized garments and optional sub-rollers, offering the flexibility required for responding to various customer and market needs. Realizing excellent cost performance while ensuring Made-in-Japan quality, safety, reliability and user-friendliness, N.SSR®132 sets a new standard for a new era in computerized flat knitting machines. The N.SSR®132 will be shown in 14 gauge.

SDS®-ONE APEX4 and APEXFiz®

SDS®-ONE APEX4 3D design system and APEXFiz® subscription-based design software support the creative side of fashion from planning and design to realistic fabric simulation and 3D virtual sampling. Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste. Moreover, users can take advantage of this capability not only on the design side but also on the production side. Suppliers can make proposals by leveraging their own expertise in knitting and materials, allowing accelerated product development. When a design is approved for production, knitting data which is automatically generated can be converted easily into machine data, digitally bridging the gap between design studio and factory. SDS®-ONE APEX4 and APEXFiz® help to realize sustainability while digitally transforming the fashion supply chain. The product planning capability of APEXFiz® is enhanced by several web services which will also be demonstrated along with SDS®-ONE APEX4 and APEXFiz®.