#Knitting & Hosiery

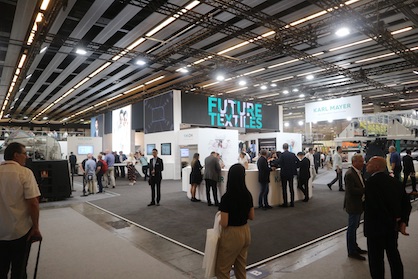

KARL MAYER presents one-stop-shop for the business success of its customers

At the KARL MAYER online stand, the visitors will find a future-oriented solution portfolio for two of the most important stitch formation techniques – warp knitting and flat knitting. The company will also introduce trendsetting innovations in the areas of technical textiles, warp preparation, weaving and digitalisation. These offers can make the business activities of its customers more successful.

In the warp knitting area, the presentation focuses on the HKS 3-M ON, the latest generation model in the portfolio of extra-wide high-performance tricot machines. The newcomer is 15% faster than its predecessor and even easier, and therefore quicker, to operate. Above all, however, it offers the greatest possible scope when it comes to patterns design and production.

Other highlights at the KARL MAYER trade show presentation include an environmentally-friendly and economical indigo dyeing process for denim manufacturing and technical textiles, which are extremely popular in the construction industry and for infrastructure projects. In this area, the video presentation of a WEFTTRONIC II G is likely to attract much attention. There is particularly a great demand for this weft-insertion machine from glass fibre plaster grid and geogrid manufacturers.

With its exhibits, KARL MAYER will also be focusing on the lucrative market of everyday face masks. The company has developed various textile solutions for this which the customers can realise on their ordinary warp and standard flat knitting machines that will helps them to stand out from their competitors.

Other offers that are bound to be in demand right now are designed to strengthen the resilience of its customers. They include well-thought-out software products and offer the customers the autonomy they need to be able to act efficiently in dynamic markets at all times. For example, an innovation from the product category k.innovation by KM.ON makes it possible to speedily develop trendy warp knitting patterns regardless of the where they are, the time and the number of creatives involved. In the flat knitting area, STOLL's new CPS – Connective Pattern Software – ensures that the creatives can achieve their goal faster, easier and more efficiently through the integration of smart features. Designers and product developers can also look forward to new ideas inspired by the latest STOLL Trend Collection "FASTER: From(CONCEPT)–To(STORE)".

The WTiN Virtual Trade Show visitors can learn more about this and other innovative solutions with just one easy click. The necessary registration is free and offered at vts.wtin.com/register.