#Knitting & Hosiery

SHIMA SEIKI to exhibit at Pitti Filati 86

The flagship MACH2XS WHOLEGARMENT® knitting machine features such innovations as the original SlideNeedleTM on four needle beds as well as the company’s patented springloaded moveable sinker system. It can knit beautiful, high quality 3D Items with dimensional structures and details that are unique to WHOLEGARMENT®, all with very high efficien cy while minimizing dependence upon laborintensive sewing and linking. Produced in its entirety on the knitting machine, WHOLEGARMENT® is sustainable knitwear that consumes only the minimum amount of materials required for that item.

SFG20 carries on SHIMA SEIKI’s glove knitting machine manufacturing tradition with its original sinker knitting system, but this time in ultrafine 21 gauge. New features such as a removable needle selection drum and beltdriven carriage improve productivity and ease of maintenance.

Continuing from the last edition of Pitti Filati, SHIMA SEIKI is collaborating with Italian designer Vittorio Branchizio and several Italian yarn companies for producing knitted garment and glove samples especially for the show.

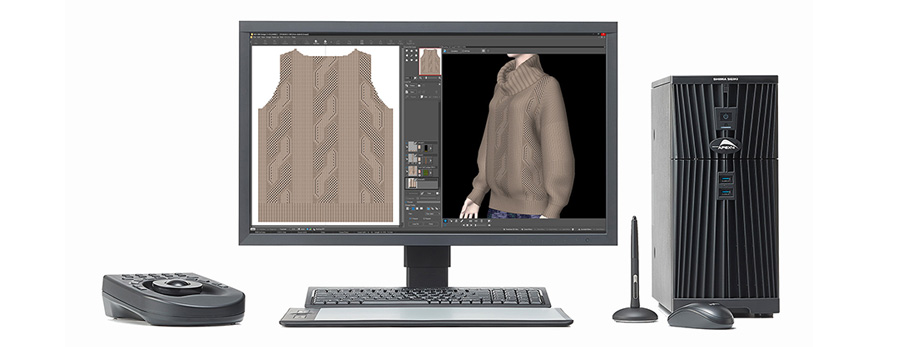

Also on display at Pitti Filati is SHIMA SEIKI’s new SDSONE APEX4 design system, the fourth generation of its series and the most powerful, most efficient APEX to date. Processing speeds for programming and simulation are improved by up to 600 per cent compared to the previousgeneration SDSONE APEX3, for quicker response especially in virtual sam pling. Virtual sampling based on ultrarealistic simulation improves on the design evaluation process by minimizing the need for actual samplemaking. This realizes significant savings in time, cost and material, contributing to sustain able manufacturing.

Exhibition Details

Date: Wednesday, 22nd Friday, 24th January, 2020

Hours: 9:00AM 6:00PM (final day: 9:00AM 4:00PM)

Location: Fortezza da Basso - Viale Filippo Strozzi, 1, Firenze, Italy - Tel: +39 055 49721

Organizer: Pitti Immagine S.r.l. - Tel: +39 055 36931

Booth No.: C18/19 - Fashion At Work Section - Padiglione Centrale (Central Pavilion) - Piano Inferiore (basement floor)

Exhibit:

MACH2XS153 15L - (WHOLEGARMENT® knitting machine)

SFG20 21G - (Glove knitting machine)

SDSONE APEX4 - (3D design system)