#JEC WORLD 2022

ITA demonstrates live robotic draping of reinforcement textiles at JEC World 2022 in Paris

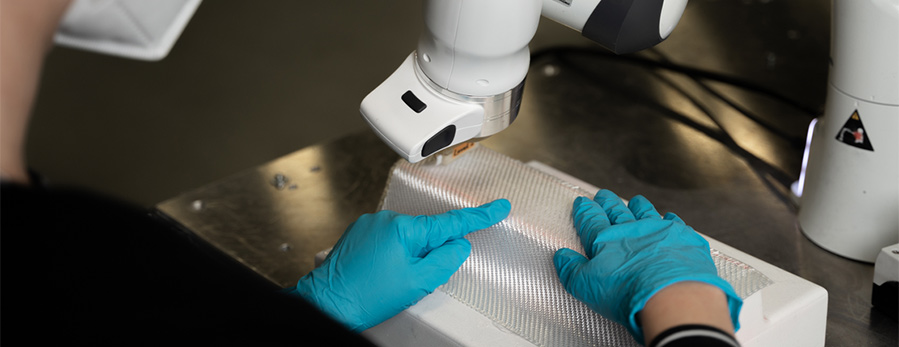

Added value through joint draping of humans and robots

ITA has developed tools that allow joint draping of textiles by humans and cobots. In addition to increasing draping quality and reproducibility, the focus in development was on occupational safety.

Other advantages of this new type of robot-assisted draping are that cobots are inexpensive to procure and easy to program. This results in great flexibility in manufacturing and the possibility to produce small to medium quantities in an automated way.

How can these advantages be exploited in the production of fibre composite components? This is what ITA is investigating, for example in the handling, draping and joining of the sensitive, limp textile material. At the JEC, visitors will have the chance to interact live with the cobot and experience collaborative draping first hand. Please contact Hannah.Dammers@ita.rwth-aachen.de for further information.

Test a live cobot interaction at our booth in hall 6 booth S50 (AZL joint booth) and experience collaborative draping first hand!

Demonstrator for mobile hydrogen storage

Another ITA exhibit is a demonstrator for mobile hydrogen storage in the form of a Type-4 pressure vessel made of fibre-reinforced composites (FRP). It is based on a specially developed liner concept and was manufactured using the multi-filament winding process with towpregs. The exhibit is additionally equipped with fibre optic sensors for strain and temperature monitoring. This enables condition monitoring through structural health monitoring. Please contact Oscar.Bareiro@ita.rwth-aachen.de for further information.

Background

ITA will be demonstrating its expertise in the field of composite materials at the joint stand of the Aachen Center for Lightweight Construction (AZL) in Hall 6, Stand S50. It will present innovations and research priorities in the production of reinforcing fibres, the textile processing of such high-modulus fibres and the impregnation of high-performance modulus fibres with thermoset as well as thermoplastic matrix systems. The ITA will show the entire process chain, from fibre production and processing to the finished component, and will thus be able to present and discuss promising innovations at all levels. It illuminates the issues of composite production and processing from the textile side. The institute's expertise lies in the characteristics of reinforcement and matrix materials, load-oriented textile processing and the manufacture of components made of continuous fibre-reinforced plastics.

The Aachen Center for Lightweight Construction (AZL) as a superordinate partner as well as the partner institutes and companies at the booth cover further topics of FRPs. These are, for example, the load-compliant design of components, plastics-side processing, and extensive testing of components.