#Industry 4.0 / Digitalization

Reifenhäuser NEXT: Tackling the skills shortage and achieving operational excellence with industrial AI

The figures speak for themselves: in Germany, 86 percent of companies are affected by the shortage of skilled workers – more than twice as many as ten years ago. The global average is currently 74 percent*. Production companies rank fifth in the industry comparison. The low availability and high turnover of experienced production specialists is one of the biggest challenges facing the plastics industry.

*Source: MPG study on the shortage of skilled workers in 2025

With Reifenhäuser NEXT, plastics manufacturers can reduce their dependence on highly qualified personnel and increase their overall equipment effectiveness (OEE) by optimizing availability, performance, and quality. This is made possible by a unique ecosystem that combines state-of-the-art AI technologies with Reifenhäuser's proven expertise and live data from production.

“Google, OpenAI, and others are already impressively demonstrating what AI solutions can achieve in the consumer sector. However, AI is only as intelligent as the data it has been trained with,“ explains Jan Karnath, Chief Digital Officer (CDO) of the Reifenhäuser Group and responsible for the NEXT brand. “Reifenhäuser has decades of experience in plastics extrusion. We have integrated this bundled knowledge into an AI solution that is unique on the market."

The Reifenhäuser NEXT portfolio is based on three product streams that seamlessly interlock:

NEXT.AI – Intelligent assistance systems

At the heart of NEXT.AI is an AI chatbot that provides real-time support to machine operators and service teams during ongoing operations. The AI accesses Reifenhäuser's comprehensive expertise in engineering, service, maintenance, and process technology – and, if desired, on the user's documentation and live production data. Operators receive immediately actionable recommendations via simple text entries (prompts) in the chatbot – for example, in the event of quality problems. Thanks to this support, even inexperienced employees can achieve optimal results. This reduces downtime, lowers service costs, and makes production processes more efficient.

“Our assistance systems act as constant companions for the production teams. They not only provide quick solutions to problems, but will also deliver proactive alerts and optimization suggestions in the future,” says Karnath.

NEXT.Learning – Knowledge as the key to success

To build up and establish the necessary expertise among plastics processors in the long term, NEXT.Learning offers a combination of on-site training and a digital learning platform. This is individually tailored to the needs of customers and helps producers to retain expertise within the company despite staff turnover and make it available to new employees at any time. Thanks to the use of AI avatars, customers can access the virtual training courses in over 100 languages. On request, Reifenhäuser NEXT can also adapt and provide content very quickly to meet customer-specific requirements.

“By using natural language processing (NLP), we are democratizing specialist knowledge for our global customer base in a whole new dimension. Initial pilot projects have generated extremely positive feedback and highlight the added value of our solution – especially for international customers whose production employees speak different local languages and, for example, do not have sufficient English skills,” explains Karnath.

NEXT.Data – Generating added value from data

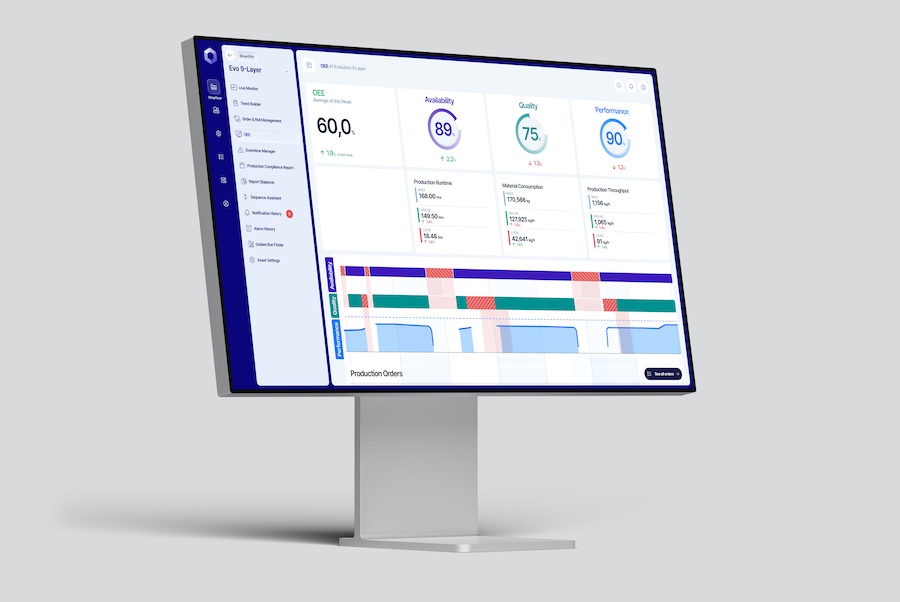

The third product stream, NEXT.Data, enables producers to exploit the full potential of their production data. The data is automatically aggregated via robust system integrations (e.g., OPC UA or GraphQL) and displayed in clear dashboards using the ExtrusionOS application suite. ExtrusionOS is specially designed for the requirements of the plastics extrusion and packaging industry. Among other things, customers can use it to create real-time analyses and automated OEE calculations to make data-driven decisions.

“With Reifenhäuser NEXT Product Streams, we provide our customers with a customized industrial AI journey. Depending on their requirements, we combine our NEXT.AI, Learning, and Data solutions, select the appropriate level of integration, and thus create the basis for operational excellence in line operation,” explains Karnath.

Recent studies show that the use of Industrial AI offers considerable potential for increasing overall equipment effectiveness (OEE) – with improvements of up to 15 percent. Among other things, this is made possible by reducing downtime and waste by up to 20 percent*. In addition, cost savings are expected in the area of maintenance, which can be achieved through optimized service and spare parts planning. Reifenhäuser NEXT focuses on precisely this area and supports companies in integrating the use of AI into industrial production in a targeted manner in order to fully exploit this potential and achieve sustainable improvements.

*Source: McKinsey / Deloitte

At K 2025, Reifenhäuser NEXT will present its solutions and corresponding product demonstrations in Hall 17, Booth C22 at the Reifenhäuser Group stand.