#India ITME 2016

Savio comes with full commitment to the Indian Textile industry to ITME

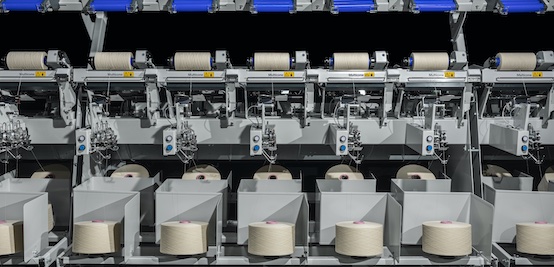

Savio will exhibit in Mumbai breakthrough innovations both in winding and twisting segment.

The latest innovation, Eco PulsarS winding machine, will be displayed for the first time to the Indian market, after the launch in Milan last year and the roadshow in Turkey and China.

There are important Savio’s products on display at Itme, all representing high-end and niche products with important technological content:

- Eco PulsarS winding machine, latest model with sustainable eco-green advantage;

- Sirius TFO twisting machine, the worldwide flagship in high-end TFO segment.

Spindles and bobbins feeding systems set independently the level of suction required. Suction is generated as needed and used without losses. The new Controlled Cut System, Yarn Tension Control System, Waste Collection&Separation System and Upgraded Splicing Solutions, each contributing to the overall reduction of the process downtimes.

Benefits:

- EcoPulsarS with its innovative platform can save up to 30% power bill thanks to "Suction on Demand" system

- New Controlled Cut System to reduce repetitions

- New Yarn Tension Control System

- Innovative Waste Collection & Separation system to reduce and recycle yarn waste

- Friendlier to the user: machine control and diagnostics

This new model foresees a high structural standardization, a wide range both for feeding and spindle dimensions for every yarn type and count, electronic solutions to simplify the operator intervention and reduce the maintenance workforce. The Electronic Drive System (EDS) version differs from the mechanical version for the full flexibility of setting adjustments. The Sirius EDS model is equipped with independent inverters and motors, which allow setting all processing parameters by the machine PC.

Benefits:

- Widest range of feeding solutions.

- Great selection of optional, covering all needs.

- E.D.S. (Electronic Drive System) and Inverter solutions to minimize setting downtime and enhance flexibility.

- Two-for-one twisting and precision winding in one solution.

Pic: SIRIUS TFO twisting machine