#ITMA Asia + CITME Singapore 2025

Picanol to exhibit latest weaving technology at ITMA ASIA + CITME, Singapore 2025

“We’re incredibly excited to be showcasing our latest developments at ITMA ASIA + CITME,” explains Johan Verstraete, Vice President Weaving Machines. “A key highlight is the new OmniPlus-i Connect, which integrates groundbreaking innovations across all four of our design principles. One standout feature, EcoBoost, enables energy savings of up to 1.5 kW per weaving machine. This is a true game-changer for mills that are aiming to reduce operational costs and environmental impact. This is not just evolution – it’s setting a new benchmark.”

Whether focused on airjet or rapier weaving, or on accelerating digital transformation, Picanol’s comprehensive range of solutions is designed to help weaving mills stay ahead. Visitors will also have the opportunity to experience AI-powered applications within the PicConnect platform, Picanol’s centralized digital ecosystem that integrates all digital tools and services in one intuitive interface.

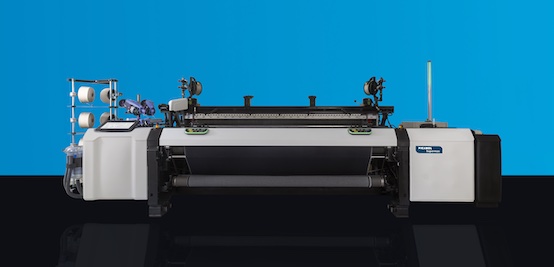

At the Picanol booth, four weaving machines will be on display. The main attraction will be the OmniPlus-i Connect airjet weaving machine, presented for the first time in its new generation. The machine combines digitization, maximum flexibility, and top-level energy efficiency while maintaining the highest industrial speeds. With features such as EcoBoost, AirStream, and EcoWeft, it offers measurable power savings and process reliability. The system also integrates Picanol’s latest automation tools – including Pick Repair Automation, AutoSpeed, and Prewinder Switch-Off – as well as smart monitoring options for power and air consumption. The result is a platform that delivers both technological excellence and practical advantages for cost-effective, sustainable weaving.

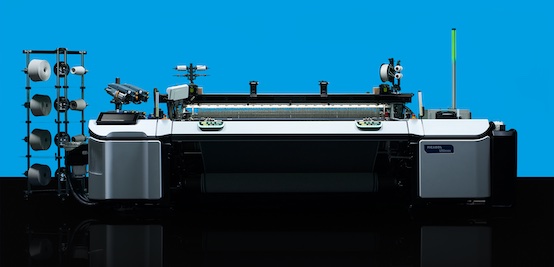

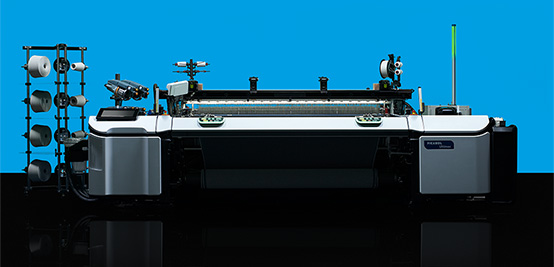

Alongside the new airjet model, two rapier weaving machines will also be demonstrated: the Supermax and Ultimax. The Supermax offers an ideal solution for weaving top-quality jacquard fabrics up to 380 cm, ensuring maximum versatility and ease of operation. The Ultimax, on display in a configuration for coating fabrics, combines high production speeds with outstanding fabric quality and advanced digital control.

In addition, visitors can see another OmniPlus-i Connect airjet machine for high-end sheeting applications and an Ultimax rapier weaving machine with Jacquard at the Vandewiele booth (Hall 2 – C301). The PicConnect Corner at Picanol’s booth will present the full functionality of the platform, connecting all displayed machines and demonstrating how industrial IoT and digital services can optimize weaving performance.

For more than 85 years, Picanol has played a pioneering role in the global textile industry and is today a world’s leading manufacturer of weaving machines based on airjet and rapier technology. In addition to weaving machines, the company offers upgrade kits, spare parts, training, troubleshooting, and digital services through its PicConnect platform. Headquartered in Ieper, Belgium, Picanol employs more than 1,200 people worldwide and is part of Picanol Group, a business unit of Tessenderlo Group (Euronext: TESB), a global industrial group active in agriculture, valorization of bio-residuals, machinery, electronics, energy, and industrial water management solutions.