#ITMA Asia + CITME Singapore 2025

Advanced automation from Sweden in Singapore

“The push for automation, AI-driven production and digitalisation continues to accelerate as manufacturers seek to improve efficiency and reduce dependency on repetitive tasks for operatives,” says TMAS Secretary General Therese Premler-Andersson. “Advanced automation enables predictive maintenance and real-time quality monitoring in fully integrated production systems and our members are already exploiting these technologies to help customers reduce downtime, improve efficiency and produce more sustainably.”

Single supplier

Under its trademarked slogan ‘Complete Process – One Supplier’, for example, ACG Kinna Automatic (at Hall 6, stand D106 in Singapore) has pioneered the development of complete robotic lines for the production of pillows and duvets for the home furnishings sector – from the handling and opening of filling material and full line fabric feeding to sewing, digital quality control and packing.

Under its trademarked slogan ‘Complete Process – One Supplier’, for example, ACG Kinna Automatic (at Hall 6, stand D106 in Singapore) has pioneered the development of complete robotic lines for the production of pillows and duvets for the home furnishings sector – from the handling and opening of filling material and full line fabric feeding to sewing, digital quality control and packing.

Just a few years ago, such lines were seen by manufacturers as something exciting to perhaps consider for the future, but suddenly they have become essential to competing and surviving in today’s fast-moving industry.

“Automation has become a must for a number of reasons,” says ACG Kinna Marketing and Sales Manager Tomas Aspenskog. “Product traceability, flexibility and local production, in addition to new trade regulations, are now driving the market and given the challenge of finding skilled operators and constantly increasing costs, manufacturers are looking for simpler systems that will save on resources and boost productivity wherever possible.

“Our modular solutions enable customers to be more flexible and faster in adapting specific parts of a production line to meet new demands, and also to grow over time. There are also many benefits for manufacturers in dealing with only one project leader, contact person, supplier, freight handler and installation team.”

Industrial sewing

In Singapore, ACG Kinna Automatic will introduce the new Hector industrial sewing machine designed for the heavy duty circular and point stitching of filled textile components such as garden cushions, outdoor pillows and mattresses. Hector is already being employed by leading Swedish retailers including IKEA and JYSK in their manufacturing operations.

The Hector’s sewing arm is adjustable and can open up to accommodate thicker items under the needle and presser foot. It is available in three versions with sewing arms in lengths of 60, 100 and 120 centimetres.

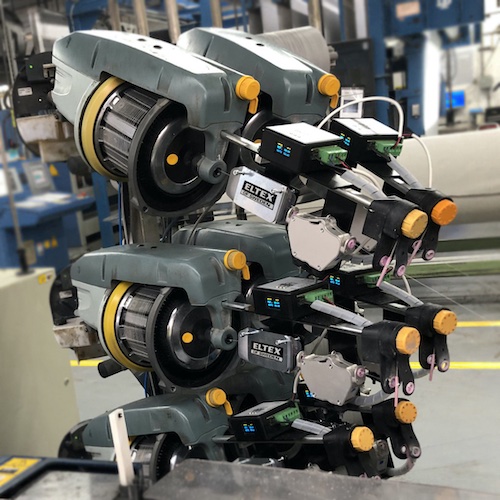

Eltex EyETM

Another TMAS member, Eltex (Hall 2, stand C203) has made an important breakthrough on its EyETM tension monitoring system for the heat setting, tufting, warping and winding sectors, with the addition of electromagnetic brakes in combination with the latest advanced sensors. These enable tension variation to not only be detected, but automatically adjusted in real time during operation, rather than manually changed as previously.

The company’s ACT-R unit can further significantly reduce the selvedge yarn waste from the weft insertion systems of rapier weaving machines, while at the same time maintaining equal and steady tension across all pre-winders.

“Our ACT-R is a completely plug and play, stand-alone system and self synchronizes without any communication with the weaving machine,” explains Eltex Sales Engineer Michél Gamhov. “This is important, because many older weaving machines are still in operation worldwide, and the ACT-R enables instant improvements to be made without upgrading these machines in any way. We have achieved fantastic results for weavers working with recycled yarns who have been amazed at the difference in consistent quality and uninterrupted production that can be achieved.

“As everyone knows, the less waste you have the more you save in materials, labour, runtime and quality and we can help mills cut losses in many of these areas depending on the challenges they are facing. Many of our sensor-based systems are able to give older textile machines a new life and in Singapore we’re looking forward to talking to customers about the problems they face, because we believe there’s even more, we can do with our advanced technologies to make their existing machines more efficient.”

Svegea tubular components

The colarette machines of Svegea (Hall 6, stand D109) set the standard throughout Asia for the high speed production of tubular apparel components such as cuffs, collars and neck tapes and in Singapore the company will demonstrate its EC 50 and EC 200 with E-Drive II models, in addition to linked cutting systems.

“Our collarette machines are designed for long life-cycle durability and energy efficiency, reducing waste while providing high-quality binding,” says Svegea Managing Director Håkan Steene. “Our customers in Asia are increasingly looking to automation to improve efficiency and achieve cost savings and we address these needs by developing flexible machines that can be adapted to a wide range of customer requirements and combine high performance with user-friendly automation features.

Vandewiele know-how

Advanced weaving control is also the bedrock of business for Vandewiele Sweden AB (Hall 2, stand D301e), which supplies weft yarn feeding and tension control units for weaving looms to the majority of the leading weaving machine manufacturers, as well for retrofitting in working mills around the world and will present its latest X4 yarn feeders with integrated accessory displays at ITMA ASIA + CITME 2024.

X4 feeders are available in three different versions – with an integrated tension display (TED), with integrated active tension control (ATC), or with quick release, which enables weft tension settings to be transferred from one machine to another, enabling a fast start-up the next time the same article is woven. The position of the S-Flex Tensioner is constantly monitored by an internal sensor – even if adjustment is made during power off.

Vandewiele Sweden has recently further strengthened its product portfolio with IRO Gaugepart modules which are applied to tufting looms for the carpet industry, to determine the appearance of a carpet in terms of feel and structure. All parts are now available to order from the www.iroonline.com e-commerce site.

“Our size and flexibility mean that we can offer bespoke customer solutions according to specific requests – something that many larger manufacturers have difficulty matching,” says Division Manager Tobias Sternfeldt.

Spray technology

Finally, the automated Texcoat G4 finishing system of BW Converting (Hall 8, stand B201) has been a runaway success in the past few years and the company will announce an entirely new, but related technology shortly before the Singapore exhibition.

“TexCoat G4 spray technology was developed in Sweden from our off-set printing business and we initially focused on installing units in Europe and the USA,” explains the company’s Vice President of Global Business Development for Textiles Rick Stanford. “In the past two years, however, we have been very active in Asia, with 35 units sold – and many of these customers have been asking for technologies in related areas. We’ll be saying more very shortly. ”