#ITMA Asia + CITME Singapore 2025

Barmag and Neumag showcase innovations at ITMA Asia

The increasingly complex world of textiles demands individual solutions that can be flexibly adapted to constantly changing market conditions. Barmag supports its customers with appropriate plant concepts and complete solution packages. Artificial intelligence has become an integral part of this world.

Bringing atmos.io to the networked factory

atmos.io is the operating system for intelligent yarn production. Every machine – whether a pilot plant or large-scale production with hundreds of positions – comes with the digital core. This makes atmos.io the basis for the smart factory. In the integrated app store, yarn manufacturers can put together exactly what they really need. atmos.io provides data-based decision-making criteria – objectively, efficiently and with a focus on quality. It digitizes the entire material flow: every bobbin carries its own data, from the melt to the warehouse. This allows yarn manufacturers to intervene in production at any time – quickly, precisely and profitably. The advantages: less waste, higher yarn quality, less effort for shop floor employees. The system integrates seamlessly into existing production and IT infrastructures. atmos.io relies on an intelligent data infrastructure that meets the highest standards of cyber security while providing consistent, trustworthy data for secure and efficient process control.

The future of filament spinning

Flexibility is the core competence of WINGS FDY FLEX, the latest winding concept for the FDY process. With an enormously wide production window, WINGS FDY FLEX is the perfect solution for short-term product changes and a wide range of yarn products. It can even process recycled polyester. This makes the FDY process with WINGS FLEX future-proof and sustainable.

What does the future hold for the POY process? Yarn manufacturers can also find out at the Barmag booth. The Barmag experts will be presenting the next generation of POY production to selected visitors – and will also be offering a captivating insight into the future of textiles.

eFK EvoSmart – innovation meets efficiency in yarn texturing

With the new eFK EvoSmart texturing machine, Barmag presents a machine concept based on the globally proven manual eFK that meets the highest quality requirements and sets new standards in operational efficiency. With a focus on energy-efficient yarn production, the eFK EvoSmart offers technological features that sustainably reduce both energy consumption and operating costs – with-out compromising on quality and process reliability. By combining energy-optimized process control with innovative components such as EvoHeater and Smart Godets, the eFK EvoSmart achieves a significant reduction in specific energy consumption – with potential savings of 25% per kilogram of yarn. The simple replacement of the heater inserts eliminates the need for time-consuming mechanical and chemical heater cleaning inside the machine. The system consisting of EvoHeater and adapted suction not only saves energy but also doubles the maintenance intervals. This reduces the maintenance requirements of the eFK EvoSmart by 50%. Shorter and less frequent downtimes increase productivity and ensure higher plant availability. Whether in weaving, knitting or finishing, consistent performance ensures smooth processes and the best results.

Concentrated innovative strength for staple fiber production

Oerlikon Neumag is setting new standards in the production of synthetic staple fibers with several technological innovations. At the heart of these innovations is the state-of-the-art EvoSteam process, which not only offers significant energy savings but also raises fiber quality to a new level. The ad-vantages over conventional processes are clear: more efficient, more sustainable and more powerful.

The EvoSteam concept is complemented by EvoDuct and EvE-2, two further pioneering developments for staple fiber spinning. EvoDuct optimizes the air flow distribution in the air supply. The result: lower pressure drop, less energy consumption and a more uniform air flow, which has a positive effect on fiber quality and fiber uniformity. EvE-2 revolutionizes monomer and hot air extraction. The newly designed extraction nozzles minimize air turbulence and improve the uniformity of the air supply. The external monomer extraction facilitates maintenance work and significantly increases spinning performance.

Another highlight: the automated spin pack wiping robot, already used in filament spinning by Oerlikon Barmag, now also cleans the spinning packages in the staple fiber process. The advantages are the same: consistent, excellent wiping quality, extended cleaning intervals, reduced personnel costs, savings in consumables, environmentally friendly and healthy, controlled silicone spray consumption and synchronization of cleaning cycles with can change and splice management.

New standards in BCF yarn production

With the new BICO BCF technology, Oerlikon Neumag is launching a completely new type of yarn that takes carpet performance to a new level: higher pile strength, improved recovery properties and approx. 20% less face fiber consumption – without compromising the brand's renowned high quality. The result: lighter carpets with the familiar high-quality characteristics of Oerlikon Neumag yarns.

Also new to the portfolio: FiberGuard BCF – an intelligent system consisting of sensors and software that measures the yarn tension between twisting and winding in real time. The software reacts automatically to deviations and adjusts the process independently. This means less waste, higher efficiency and greater sustainability. And best of all, FiberGuard is compatible with all current BCF machines, or can be retrofitted.

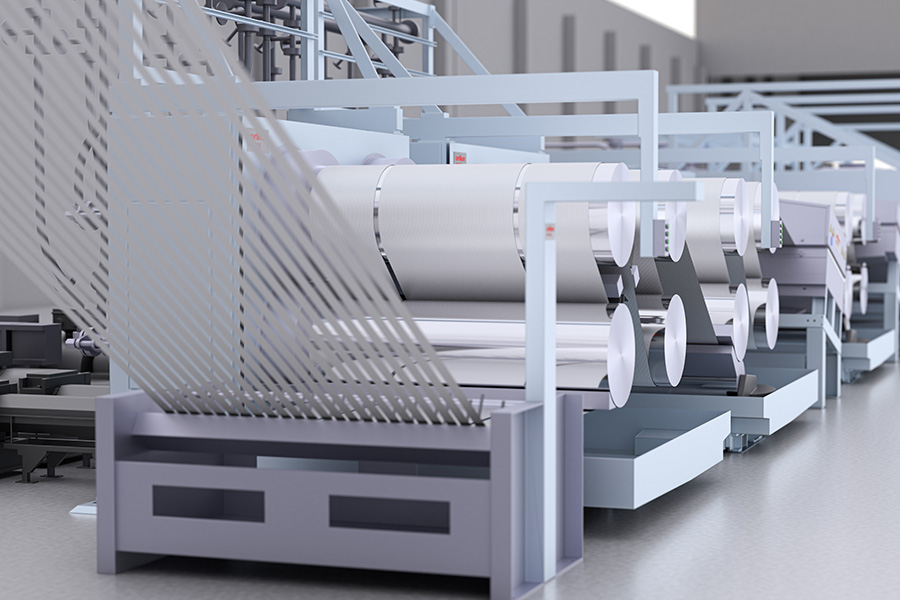

Highly efficient nonwovens technologies

At the heart of this is Oerlikon Nonwoven's patented hycuTEC unit – a real revolution for the filtration industry. Using osmosis-treated water, the system enables a high electrostatic charge to be applied to polypropylene meltblown nonwovens – with an impressive efficiency of 99.99%.

The brand also impresses in the Spunbond sector with high-performance production lines. Its potential is particularly evident in water filtration, for example through the implementation of a BiCo process utilizing polyester and co-polyester polymers.