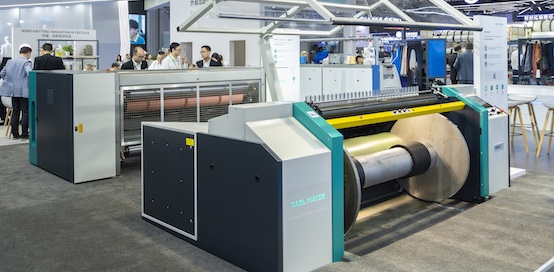

#ITMA Asia + CITME 2024

Shanghai – Stäubli's latest innovations for boosting weaving efficiency

Stäubli is constantly offering new and improved high-performance systems and solutions for processing woven fabrics for various sectors including fashion, home textiles, automotive, protection, medical and carpeting as well as highly complex technical textiles for aeronautics and future applications.

At ITMA ASIA 2024, only one year after the last edition, the company is again presenting novelties. From automation in the weaving mill to the intricate process of perfect shed formation – even for the most complex Jacquard fabrics – Stäubli Textile is presenting an overview of solutions designed for performance, durability, and thus profitability of the weaving mill.

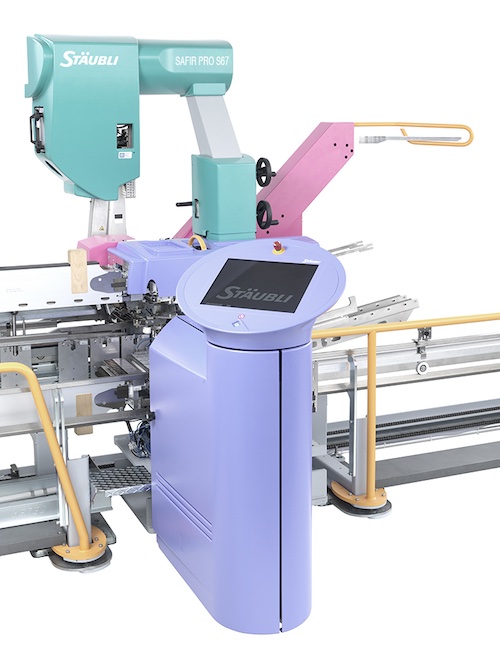

A world premiere is being unveiled at ITMA ASIA+CITME: the SAFIR PRO S47 drawing-in machine, which is perfectly adapted to the needs of the Chinese market. It features innovative AWC 2.0 (see below) and Layer and Offset Management for efficient automatic drawing in of double-warp-beam applications for staple fibers and especially fancy denim applications.

Streamline your operations with Stäubli Textile machinery and solutions

Visitors to the Stäubli booth will see a wide range of machines and systems for efficient weaving preparation, frame and Jacquard weaving, and carpet and technical weaving.

Weaving preparation is fast and efficient with the MAGMA warp tying machine, which is easy to use and ensures perfectly tied warps.

Style changes – Automation – Active Warp Control 2.0

Yarn detection faster than the eye can see. The SAFIR PRO S47 is equipped with state-of-the-art AWC 2.0 technology. Using image processing, data analytics, advanced algorithms & software, and high-performance processors, AWC 2.0 instantly interprets measured data and controls every thread. This gives mills expanded capabilities to produce innovative, outstanding, and unique designs.

Lower your energy consumption. The LX PRO and N4L PRO Jacquard machines being demonstrated feature the innovative MX PRO module, controlled by NOEMI electronics architecture and the TC8 controller. These energy-efficient Jacquard machines promise weavers outstanding reliability and ease of use.

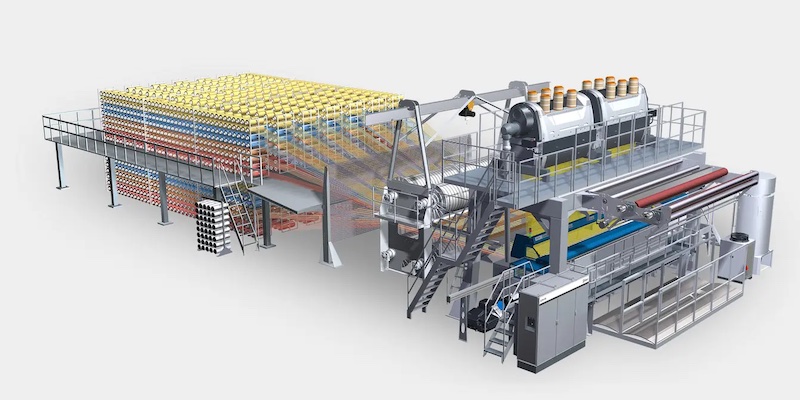

Latest binding techniques – Also on display will be new carpet weaving innovations that can ideally meet Chinese market requirements. Designed for rapid style changes and sophisticated weave structures, the ALPHA 580 UNIVERSAL carpet weaving machine can produce a variety of carpet qualities at up to 5.3 m weaving width. With convenient yarn handling, high operational reliability, and long service life, this machine is an exceptional solution for carpet weaving mills. A broad selection of impressive carpet samples will be on display at the Stäubli booth.

Digital solutions for optimized processes in weaving mills

The MyStäubli customer portal includes an equipment center to support efficient maintenance in your weaving mill and help you get the most out of Stäubli machinery and solutions. This makes it easy for mills to take proper care of their machinery, optimally train their teams, expand their knowledge, and take advantage of the redesigned e-shop for simple management of spare parts. MyStäubli is a multifaceted solution designed to suit every weaving mill’s technical and personal needs, recognizing that each weaving mill is one of a kind. Stäubli respects that, which is why a broad spectrum of interaction options has been integrated into MyStäubli.

Weaving mills can now register with MyStäubli to discover Stäubli's comprehensive support platform. Stäubli looks forward to welcoming you to the Stäubli booth D09 in Hall 3 at ITMA ASIA + CITME.