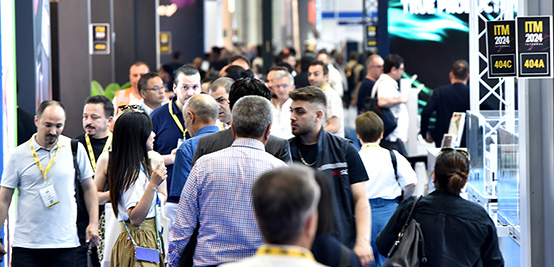

#ITM 2024

Rieter at ITM 2024: Raising the bar on performance with automation, digitization and recycling

To this end, Rieter presents a range of compelling solutions at ITM 2024 designed to automate, digitize and optimize operations, so that mill owners can successfully address the current market situation and expand their competitive advantage. Rieter’s digital spinning suite ESSENTIAL plays a key role in helping mills realize their full potential.

ROBOspin – enhancing profitability and optimizing labor management

Each week in spinning mills across the globe, ROBOspin pieces more than 1 000 000 yarn breaks, resulting in a reduction of about 2 000 working hours for operators. Automated piecing for ring and compact-spinning machines with the fully automatic piecing robot ROBOspin is the key for increasing profitability and streamlining labor management.

SSM DP5-T – high quality air textured filament yarns

To meet the needs of the region’s strong air textured yarn market, Rieter through its subsidiary SSM offers the DP5-T for processing partly-oriented yarns and fully-drawn yarns into unique air textured yarns. With a variety of exclusive fancy options, DP5-T unlocks limitless creative possibilities for customers in the final application.

C 81 – outstanding carding results thanks to intelligent sensors

With high production rates and excellent sliver quality, the card C 81 gives spinning mills a strong position in the market. Intelligent sensors make this possible by consistently setting the carding gap to the ideal size and monitoring in real time the trash level of the card infeed and the sliver that is produced.

Newest draw frame generation – superior sliver quality and efficiency

The newest draw frame generation of single and double head draw frames

RSB-D 55, SB-D 55 and RSB-D 27, SB-D 27 upholds the tradition of superior sliver quality and efficiency. It features reduced operating and maintenance costs. Thanks to innovative technical solutions, recycled fibers can be processed to optimum effect.

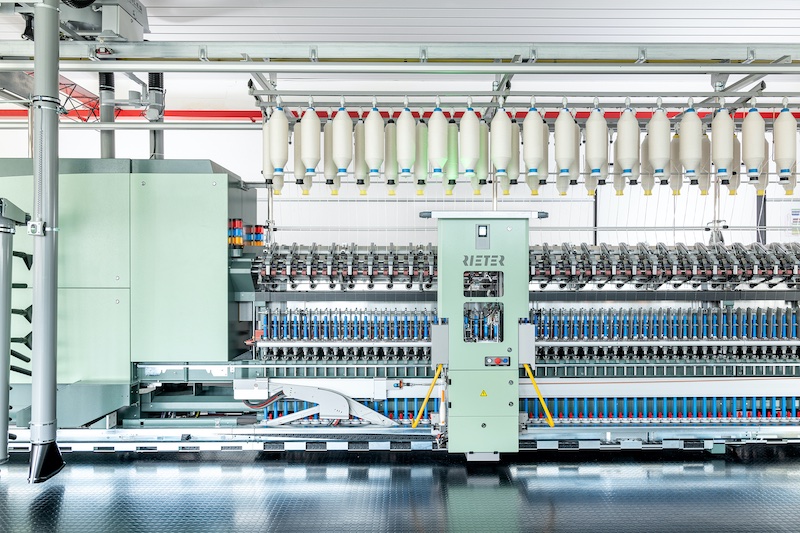

G 38 – highest production in ring spinning on the market

The latest generation of the ring spinning machine G 38 offers highest spindle speeds of up to 28 000 rpm in combination with significantly reduced machine downtime. This breakthrough is owed to a doffing-cycle time of less than 90 seconds, 12% faster cop transport with the reshaped cop transport system SERVOdisc as well as a reduced ends down rate based on balanced yarn tension peaks.

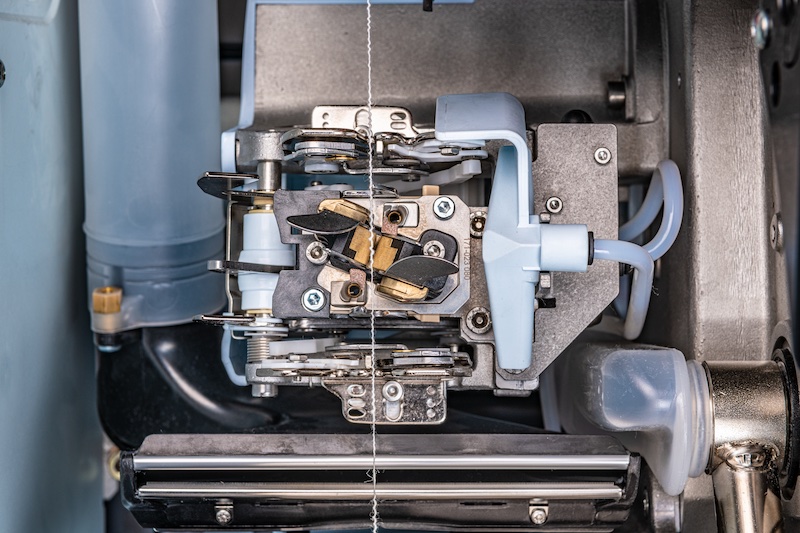

Autoconer X6 – unrivalled splicing quality, flexibility through automation

The automatic winding machine Autoconer X6 stands for efficiency, quality and flexibility. The splicers with the state-of-the-art open prism technology OZ1 and OZ2 ensure the highest levels of splice quality. With the Multilink and Multilot material flow configuration, automation becomes even more flexible and cost-effective.

Recycling toolbox – increasing recycled ring yarn quality

Rieter is introducing three tools that enable customers to achieve a high yarn quality from mechanically recycled cotton fibers that matches the standard of an average carded ring yarn made from 100% virgin cotton: pre-carding for full cleaning, combing to improve yarn quality, compacting to add the finishing touch.

Key technology components to make the difference

Key technology components from Accotex, Bräcker, Graf, Novibra, Suessen and Temco are what make the difference in the economic efficiency of spinning mills. The right components guarantee maximum machine performance, productivity and minimal maintenance – and thus an excellent return on investment.

Türkiye – unlocking growth for a leading market

Since 1974 the sales agency Erbel A.S. and service engineers and technicians from Rieter have been working together in a common mission to strengthen the competitiveness of Turkish customers. This year Haluk Erbel and Rieter are celebrating 50 years of this unique collaboration that forms the basis of the lasting success in Türkiye.

In a move to further improve its customer support, Rieter After Sales opened its first spare parts warehouse in Istanbul, Türkiye, in April 2024. The new building enables door-to-door deliveries for locally stocked spares within only 48 hours.

Rieter is pleased to present its latest innovations at ITM 2024 in Istanbul, hall 7, booth 702. As a major player in the region’s vibrant textile market, Rieter is committed to shaping its dynamic landscape with cutting-edge solutions.