#ITM 2022

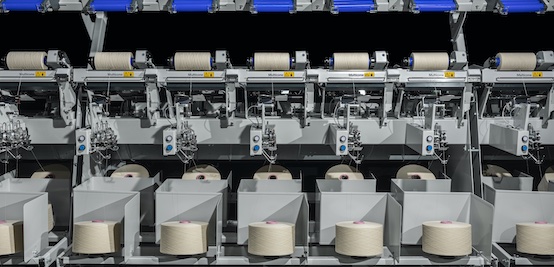

Savio at ITM ISTANBUL 2022 exhibition: solutions-oriented portfolio to maximize machinery return on investment

Savio will be exhibiting in Istanbul solutions-oriented machinery portfolio: winding, winding for continuous shrinkage, bulking and heat setting and TFO twisting.

To decide which spinning technology is best suited to your needs, Savio offers numerous solutions to support the quality of the final yarn product. To quote a few solutions for Turkish market:

SAVIO SOLUTIONS FOR DENIM YARN PROCESSING:

Savio automatic winders can easily process special yarns, such as the current very demanded product like the dual core spun yarns. The Savio winding unit is equipped with clearing, splicing and tension control devices for ensuring perfect splices and perfect package shape.

SAVIO SOLUTIONS FOR ACRYLIC YARN PROCESSING:

Many years of experience and a close collaboration with customers have allowed Savio to offer several solutions for production of acrylic yarns. The effect of the Volufil machine process gives acrylic fibers dimensional stability, higher volume, wrinkle resistance or temperature resistance, which acquires a regular geometrical structure with excellent volume. “Multicone” technology and Sirius twisting machines are also addressed to our customers producing acrylic packages for dyeing, knitting and home furnishing.

SAVIO SOLUTIONS FOR PACKAGES FOR DYEING PROCESS:

The yarn package weight and density are two important parameters which are to be standardized for uniform and trouble- free dyeing. The soft package winding is the most important pre-dyeing operation, which directly affects not only the dyeing quality but also post dyeing operations. Savio winding machines for all kind of short staple yarns, are suitable for dye package winding, warping preparation and rewinding with or without waxing devices.

SAVIO SOLUTIONS FOR CELLULOSIC and TENCEL™ FIBER YARNS PROCESSING:

According to the complexity in the production process of TENCELTM fiber, Savio pays great attention to yarn control during the winding process.

SAVIO SOLUTIONS FOR SUPER FINE YARN PROCESSING:

Savio Multicone technology and Sirius twisting machines are especially addressed to our customers producing packages for dyeing and very fine counts, from Nm 200 and above.

SAVIO looks forward to meet interested textile people at Hall 3 Booth 311A.